How to Choose DIY Mobile Phone Case Printer Equipment: The Ultimate Guide

Service Support

- ✓ Support for small batch customization

- ✓ Fast delivery worldwide

- ✓ 12-month warranty service

- ✓ Online technical support

The personalized phone case market is booming, with consumers increasingly seeking unique ways to express themselves through their mobile accessories. For entrepreneurs and businesses looking to capitalize on this trend, selecting the right DIY mobile phone case printer equipment is the most critical decision you’ll make. This comprehensive guide will walk you through everything you need to consider—from technology types and cost factors to operational requirements and profitability—ensuring you make an informed investment that aligns with your business goals.

Understanding Different Phone Case Printing Technologies

Before investing in equipment, you must understand the various printing technologies available for creating custom phone cases. Each method has distinct advantages, limitations, and cost implications that will significantly impact your business model.

Sublimation Printing

Sublimation printing uses heat to transfer dye onto materials like plastic, ceramic, or metal. The process involves printing a design onto special transfer paper, then using a heat press to sublimate the ink from solid to gas without passing through a liquid phase, resulting in vibrant, permanent designs that won’t peel or fade.

UV Printing

UV printing uses ultraviolet light to cure or dry ink as it’s printed. The process involves specialized inks that remain wet until exposed to UV light, at which point they instantly harden. This technology allows for printing on virtually any material, including pre-made phone cases, without the need for transfer paper.

Direct-to-Film (DTF) Printing

DTF printing involves printing designs onto a special film, then applying a powder adhesive before curing with heat. The design is then transferred to the phone case using a heat press. This method works well on various materials and offers excellent color vibrancy.

Key Factors to Consider When Choosing Equipment

Selecting the right DIY phone case printing equipment requires careful evaluation of several critical factors that will determine your operational efficiency, product quality, and ultimately, your profitability.

Initial Investment and Ongoing Costs

The cost of equipment varies significantly based on technology, automation level, and production capacity. Basic sublimation setups can start from a few thousand dollars, while fully automated systems like the Fully Automatic Customize Phone Case Vending Machine represent a more substantial investment but offer greater production capabilities and convenience.

When considering the Phone Case Machine Maker equipment, remember that the initial purchase price is just one component of your total investment. Factor in:

- Consumables (inks, transfer papers, blank cases)

- Maintenance and repair costs

- Software and design tools

- Training requirements

- Space and utility requirements

Production Volume and Speed

Your expected production volume should directly influence your equipment choice. If you’re planning to serve walk-in customers who expect quick turnaround, speed becomes a critical factor. For high-traffic locations, automated solutions like the iPhone Case Vending Machines can produce a custom case in minutes, satisfying customer expectations for instant gratification.

Ease of Use and Training Requirements

Consider the technical expertise required to operate the equipment. Some systems demand significant training and design skills, while others, particularly automated vending solutions, are designed for simplicity with intuitive interfaces that require minimal training. This is especially important if you plan to have employees operating the equipment rather than doing it yourself.

Material Compatibility and Versatility

Different printing technologies work with different case materials. Ensure the equipment you choose can print on the types of cases your target market prefers, whether hard plastic, silicone, thermoplastic polyurethane (TPU), or other materials. Some systems are limited to specific materials, while others offer greater flexibility.

Space Requirements

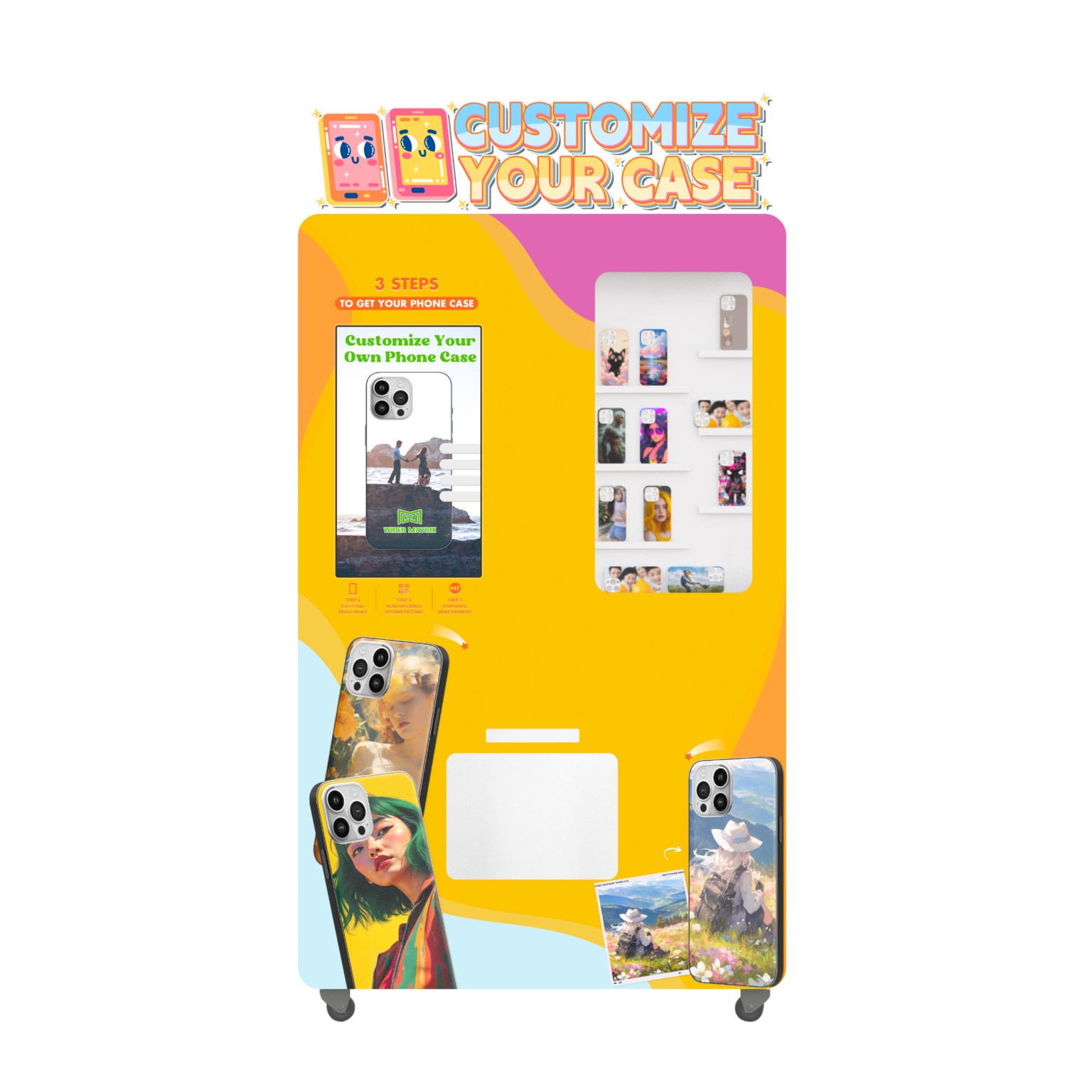

Consider the physical footprint of the equipment, especially if you’re operating in a retail environment where space is at a premium. Traditional printing setups with separate printers, heat presses, and cutting machines require significant space, while all-in-one Phone Case Printing Vending Machines consolidate the entire process into a single unit with a smaller footprint.

Comparing DIY Phone Case Printing Options

| Equipment Type | Initial Investment | Production Speed | Skill Level Required | Best For |

|---|---|---|---|---|

| Manual Sublimation Setup | $2,000 – $5,000 | 5-10 minutes per case | Moderate to High | Small businesses, home-based operations |

| Semi-Automatic UV Printer | $8,000 – $15,000 | 2-5 minutes per case | Moderate | Medium-volume businesses, print shops |

| Fully Automatic Vending Machine | $15,000 – $30,000 | 1-2 minutes per case | Low | High-traffic locations, unattended operations |

Business Considerations Beyond the Equipment

Choosing the right equipment involves more than just technical specifications—you must also consider how it fits into your overall business model and strategy.

Target Market and Location

Your target demographic and physical location (if applicable) should influence your equipment choice. A Cell Phone Case Vending Machine placed in a shopping mall targeting impulse buyers has different requirements than equipment for a custom print shop serving clients who plan their purchases.

Scalability

Consider whether the equipment allows for business growth. Can you easily add capacity? Does the manufacturer offer upgraded models? Planning for scalability from the beginning can save you from costly equipment replacements as your business expands.

Technical Support and Warranty

Reliable technical support is crucial, especially for complex equipment. Choose manufacturers that offer comprehensive warranties, responsive customer service, and readily available replacement parts. Companies like Wider Matrix provide extensive support for their equipment, which is particularly valuable for entrepreneurs new to the industry.

Integration with Other Business Systems

Consider how the printing equipment will integrate with your point-of-sale system, inventory management, and design software. Some advanced systems offer cloud connectivity for remote monitoring and management, which can significantly streamline operations.

Cost Analysis and Return on Investment

Understanding your potential ROI is crucial when selecting equipment. Let’s break down the numbers for different scenarios:

Manual Setup Investment

- Printer: $1,500 – $3,000

- Heat press: $800 – $2,000

- Blank cases: $1.50 – $3.00 each (lower with bulk discounts)

- Ink and transfer paper: $0.50 – $1.50 per case

- Total per-case cost: $2.00 – $4.50

- Retail price: $15 – $30

- Potential profit per case: $10.50 – $27.50

Automated Vending Machine Investment

For a fully automated solution like the WM880 Smart Phone Case Vending Machine, which originally retailed for $8,100 but is now available at a limited-time promotional price of $6,000, the economics change significantly. These machines offer comprehensive compatibility with the latest phone models, diverse case styles and color options, secure product dispensing systems, real-time inventory tracking, and streamlined restocking processes.

When you purchase blank cases in bulk—such as 1000 units at the wholesale price of just $1.30 each (originally $2.20 retail)—your per-case cost becomes remarkably low. With a typical retail price of $20-35 per custom case, the profit margins become substantial, especially considering the machine can operate 24/7 with minimal supervision.

Why Consider Automated Solutions Like Wider Matrix Equipment

While traditional printing setups work well for some business models, automated vending solutions offer distinct advantages for certain applications. Wider Matrix (gz) Technology Co., Ltd. has emerged as a leader in this space, with extensive experience in automation since 2016 and a track record of exporting over 3,000 machines to more than 130 countries.

Their Phone Case Printing Vending Machine represents the future of on-demand customization, offering:

- Complete automation from design selection to finished product

- Minimal staffing requirements

- 24/7 operation capability

- Integrated payment systems

- Remote monitoring and inventory management

- Small footprint relative to production capacity

This approach to phone case printing aligns with broader trends in automated retail, similar to how fully automatic cotton candy vending machines have revolutionized sweet treat distribution and how commercial cotton candy vending machines have created new profit centers in high-traffic locations.

Related Topics

- How Much Can You Make with a Cotton Candy Machine? A 2025 Profit Guide

- Is a Cotton Candy Machine a Good Investment? A 2025 Profitability Guide

- The Ultimate Guide to Cotton Candy Factory Vending Machines: Sweet Profits & Smart Solutions

- Phone Case Machine Maker: The Ultimate Guide to Manufacturing & Customization Equipment

- The Ultimate Guide to iPhone Case Vending Machines: Innovation Meets Convenience

Conclusion

Choosing the right DIY mobile phone case printer equipment requires careful consideration of your business goals, target market, technical capabilities, and budget. While traditional printing setups offer lower entry costs, automated solutions like those from Wider Matrix provide scalability, convenience, and the potential for higher profits in the right locations. The personalized phone case market continues to grow, and with the right equipment choice, you can position your business to capture a profitable share of this expanding industry.

Remember that the most expensive equipment isn’t necessarily the best for your specific needs, and the cheapest option may limit your growth potential. Evaluate each option against your business plan, calculate potential ROI carefully, and consider starting with equipment that allows for upgrades as your business expands. With proper research and planning, your DIY phone case printing business can become a profitable venture that taps into the growing demand for personalized mobile accessories.

Specifications

| Model | WM880 |

| Device Dimensions | 128cm*87cm*230cm |

| Device Weight | 220KG |

| Power | 220W |

| Voltage | 220V/110V (Optional) |

| Payment Methods Supported | Coin/Cash/Credit Card/NFC/WeChat/Alipay |

| Printing Technology | 6-color UV printing |

| Printing Resolution | 1440DPI |

| Printing Speed | 2-3 minutes/piece |

| Supported Phone Models | 96 mainstream models |

| Phone Case Storage Capacity | 300-500 pieces |

| Display Screen | 27-inch touch display, supports video ad rotation |

| Remote Management | Supports cloud monitoring and management |

Product Certificates

CB

CN61098

UKCA

JAT24110102514136

RoHS

JAT23122602137123

Company Introduction

Wider Matrix (Guangzhou) Technology Co., Ltd. is a scientific and technological enterprise that attaches importance to R&D and user experience, We started to research and develop vending machines in 2016, and achieved a leading position in the field of unattended vending machines.

In 2019, we manufactured the first automatic cotton candy vending machine. After testing in domestic market, refining our product for years, fixing the issues you might run into while operating, the performance of our machines are stable enough and reach the standard for export finally. Till now, our machine has been exported to more than 130 countries such as the United States,Canada,Europe, Southeast Asia, Australia and Israel.

We set up overseas warehouses in the United States, Canada, Britain and Israel to provide customers with consumables and accessories support. All machines support remote control, which has the advantages of easy operation, convenient maintenance and high operating efficiency. After our cotton candy vending machines are delivered and put into use, they can bring you considerable benefits.

Every customer's success and satisfaction are the driving force for us to pursue innovation and climb the peak forever. In the future, we will uphold the business philosophy of customer first and quality first, and constantly create more good products for the market. Join us now and start your intelligent and innovative vending machine business!

Exclusive Services

Overseas Support Service

Local transfer warehouse support, ensuring your operational stability.

Custom Design

We offer machine appearance customization, branding, and large-scale custom packaging services.

Initial Tools & Spare Parts Kit

Machine comes with complementary tools and spare parts kit, including initial consumables package for early operations.

Functional Customization & Software Optimization

Custom functionality based on client needs, including hardware and software optimization updates.

Lifetime Technical Support & Updates

We provide lifetime technical support and software update services for all customers.

Frequently Asked Questions

What is the most cost-effective DIY phone case printing method for beginners?

For beginners, a basic sublimation setup typically offers the lowest entry cost at $2,000-$5,000. However, consider your long-term goals—while the initial investment is lower, the manual labor required may limit scalability compared to more automated solutions.

How much technical skill is required to operate phone case printing equipment?

This varies significantly by equipment type. Manual setups require moderate technical and design skills, while fully automated vending machines are designed for simplicity with intuitive interfaces that require minimal training. Companies like Wider Matrix provide comprehensive training and support to ensure smooth operation.What are the ongoing maintenance requirements for phone case printers?

Maintenance requirements depend on the technology. Inkjet-based systems require regular print head cleaning and occasional replacement. UV printers need lamp changes periodically. Automated vending systems typically include self-diagnostic tools and remote monitoring to simplify maintenance. Always follow manufacturer guidelines for optimal performance.How long does it take to produce a custom phone case with different equipment types?

Production times vary: manual sublimation takes 5-10 minutes per case, semi-automatic UV printers can produce a case in 2-5 minutes, while fully automated vending machines like those from Wider Matrix can create a finished case in 1-2 minutes with minimal human intervention.What types of designs can I create with different printing technologies?

Sublimation works best for full-color photographic designs but requires light-colored cases. UV printing can create vibrant designs on any color case and even add textured effects. DTF offers excellent color reproduction on various materials. Consider your design needs when selecting equipment.Are Wider Matrix vending machines a good investment for starting a phone case business?

Wider Matrix's vending machines can be an excellent investment for certain business models, particularly those targeting high-traffic locations where 24/7 operation and minimal staffing are advantages. Their machines are certified to international standards including CE, UKCA, and RoHS, and the company offers extensive support. However, the higher initial investment requires careful consideration of your target market, location, and expected volume.How do I calculate the potential profit margin for a DIY phone case business?

Calculate your per-case cost (blank case + consumables + equipment depreciation + overhead), then subtract from your selling price. For example: $20 selling price - $3.50 total cost = $16.50 profit per case. With automated equipment producing 20+ cases per hour, the potential daily profit can be significant in high-traffic locations.What should I look for in terms of warranty and support when purchasing equipment?

Look for comprehensive warranties (at least 1 year on parts and labor), responsive technical support (preferably 24/7 for vending machines), readily available replacement parts, and clear documentation. Manufacturer reputation and customer reviews are excellent indicators of support quality.User Reviews

Widermatrix has been so great to work with especially Taylor. Taylor sends pictures and testimonials and data to help the decision process. Once decided the process is smooth and Taylor sends updates with pictures and videos of YOUR phone case vending machine along the way. Once it arrived the 24 hr tech support was patient with me as we worked hard to get it all dialed in. The claims are real, this automated phone case dispenser is half paid back on my initial invest just after 2 months! Kids and adults love these protective case kiosks.

I bought two phone case vending machines, and they have been in operation for over three months and are very stable. The smartphone accessory kiosks have excellent reliability and require minimal maintenance.

This is my first time running a phone case vending machine business and it looks great. The automatic mobile accessory dispenser attracts many customers in my shopping mall location.

rapid response

Interested in the product? Fill out the form now to get more information.