Why Won’t My Cotton Candy Machine Make Cotton Candy? A Troubleshooting Guide

Service Support

- ✓ Support for small batch customization

- ✓ Fast delivery worldwide

- ✓ 12-month warranty service

- ✓ Online technical support

There are few things more frustrating than setting up for a fun event, only to have your cotton candy machine refuse to spin its sugary magic. Instead of fluffy clouds of sweetness, you’re left with a sticky mess, a whirring machine, and a crowd of disappointed faces. If you’re asking, “Why won’t my cotton candy machine make cotton candy?”, you’re not alone. This common issue can stem from a handful of simple, fixable problems. This comprehensive guide will walk you through the troubleshooting steps, from basic fixes to more advanced checks, so you can get back to creating perfect, delicious cotton candy in no time.

Common Reasons Your Cotton Candy Machine Fails

Before you consider replacing your machine, run through this checklist. Most issues are surprisingly easy to resolve.

1. Incorrect Sugar Type or Quality

This is the number one culprit. Not all sugar is created equal when it comes to cotton candy. Regular table sugar often contains anti-caking agents that prevent it from spinning properly.

- Use Floss Sugar: Always use specially formulated cotton candy floss sugar. This sugar has larger crystals and is free of agents that inhibit melting and spinning.

- Check for Moisture: Sugar that has been exposed to humidity will clump and not melt evenly. Ensure your sugar is stored in a cool, dry place.

2. Machine Not Preheated

Patience is key. If you pour sugar into a head that hasn’t reached its optimal temperature, it will simply melt into a liquid and drip, rather than caramelize and spin into threads.

- Wait for the Green Light: Most modern machines have an indicator light that signals when the head is hot enough.

- Preheat Time: Allow at least 5-10 minutes for the machine to fully preheat.

3. Dirty or Clogged Spinner Head

Old, burnt sugar can clog the tiny holes in the spinner head (also called the extractor or bowl). This prevents the liquid sugar from being forced through to create the fine strands.

- Clean Thoroughly: After each use, while the head is still warm, use a damp cloth or a specially designed cleaning brush to wipe away residue.

- Deep Clean: For stubborn clogs, you may need to partially disassemble the head (consult your manual) and soak it in hot water.

Technical Troubleshooting: When the Basics Don’t Work

If you’ve checked the sugar and cleanliness, the issue might be mechanical or electrical.

Heating Element Failure

The heating element is what melts the sugar. If it burns out, the head will never get hot enough. Signs of a failing element include:

- The machine takes an exceptionally long time to heat up or never seems to get hot.

- You see no visible heat waves coming from the head once it’s been on for several minutes.

Replacing a heating element is usually a job for a professional or requires ordering a specific part from the manufacturer.

Motor or Belt Issues

The spinner head must rotate at a very high speed. If the motor is failing or the drive belt is loose/broken, the head will spin too slowly to create centrifugal force.

- Listen: Unusual grinding or whining noises can indicate motor trouble.

- Observe: Check if the head spins immediately when turned on and maintains a consistent, fast speed.

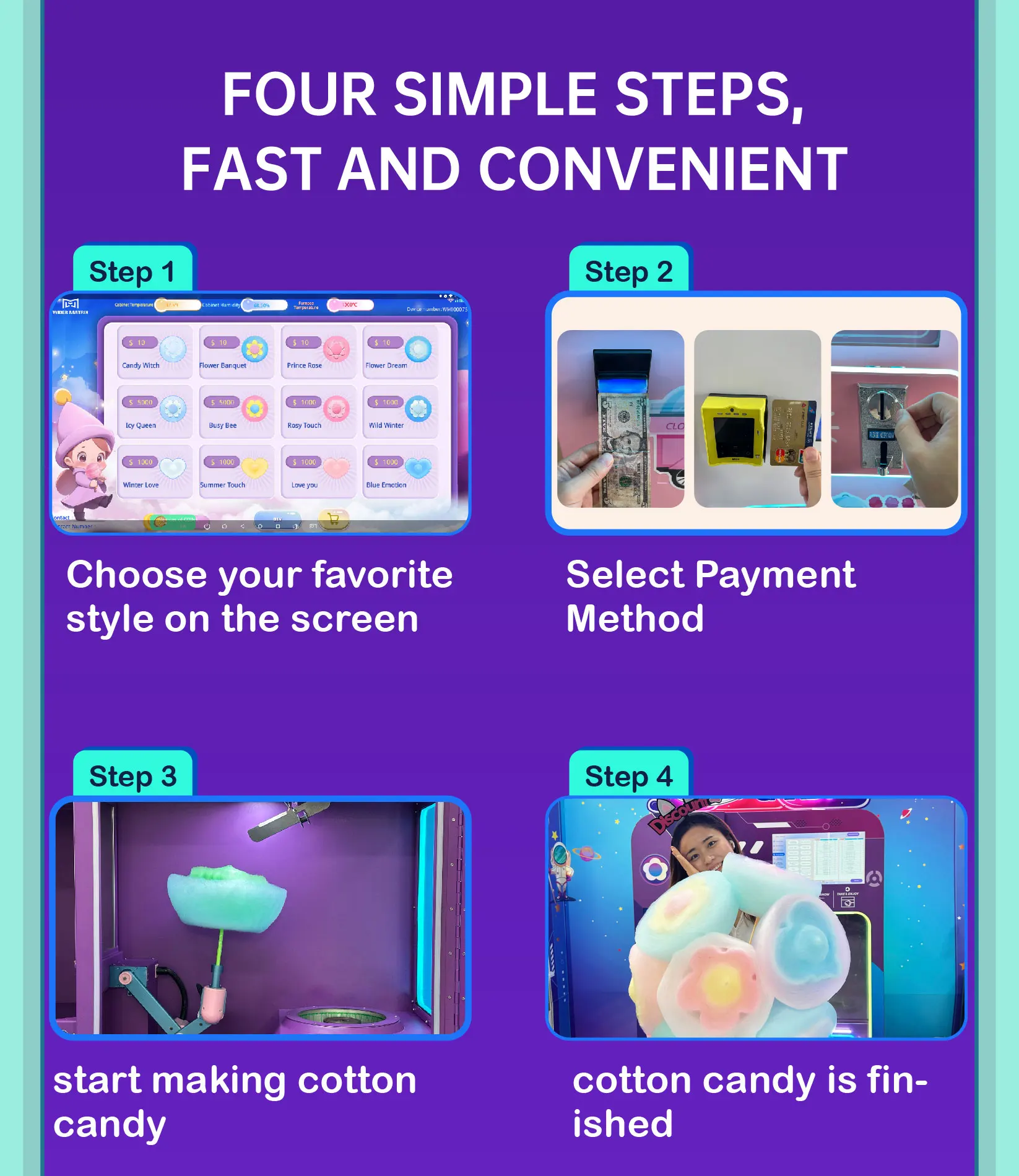

Upgrading to a Reliable Solution: The Fully Automatic Option

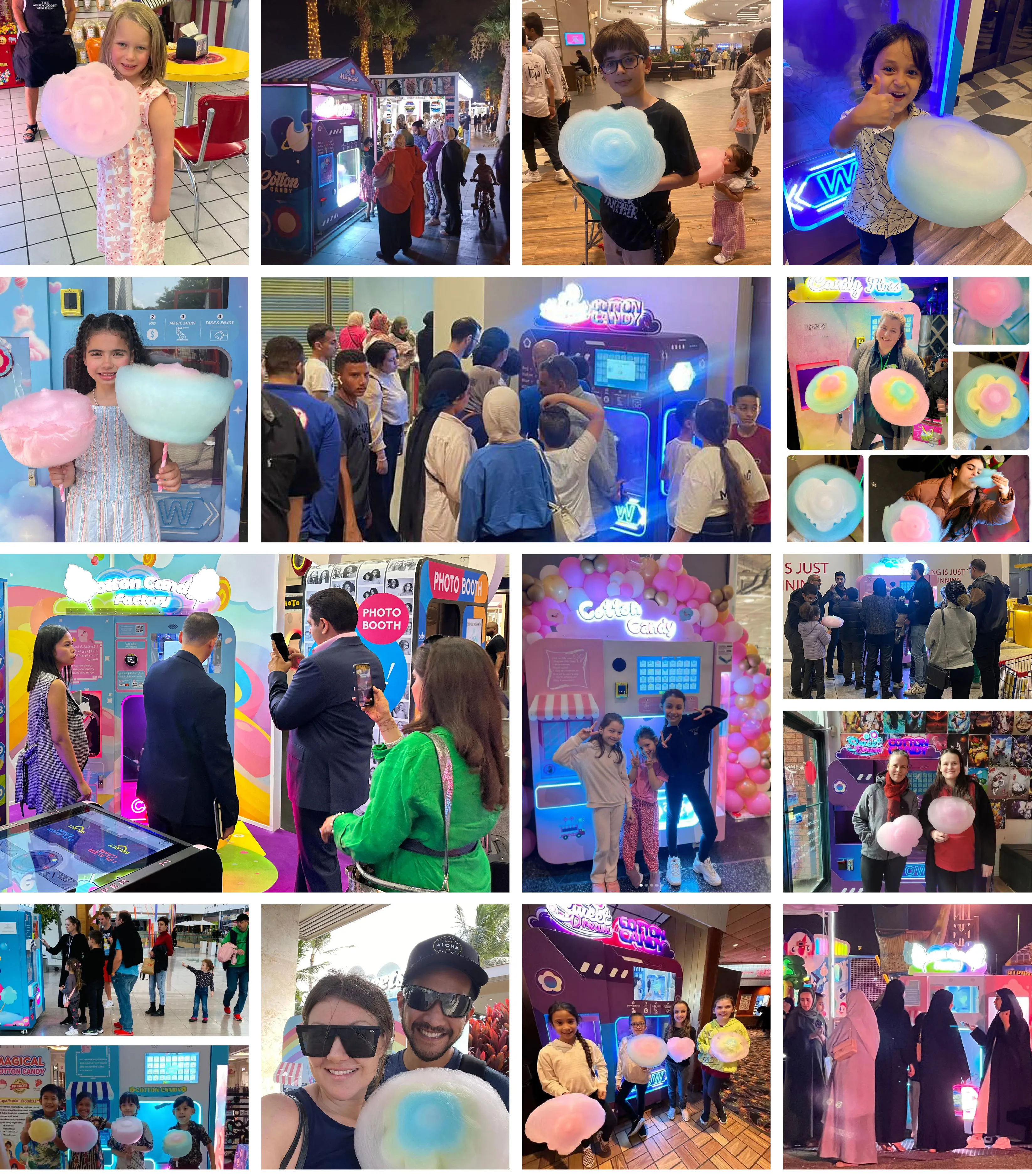

If you find yourself constantly troubleshooting a finicky machine, especially in a commercial setting, it might be time for an upgrade. Older or consumer-grade machines are prone to the issues listed above. Modern vending machines, particularly commercial cotton candy vending machines, are engineered for reliability and consistency.

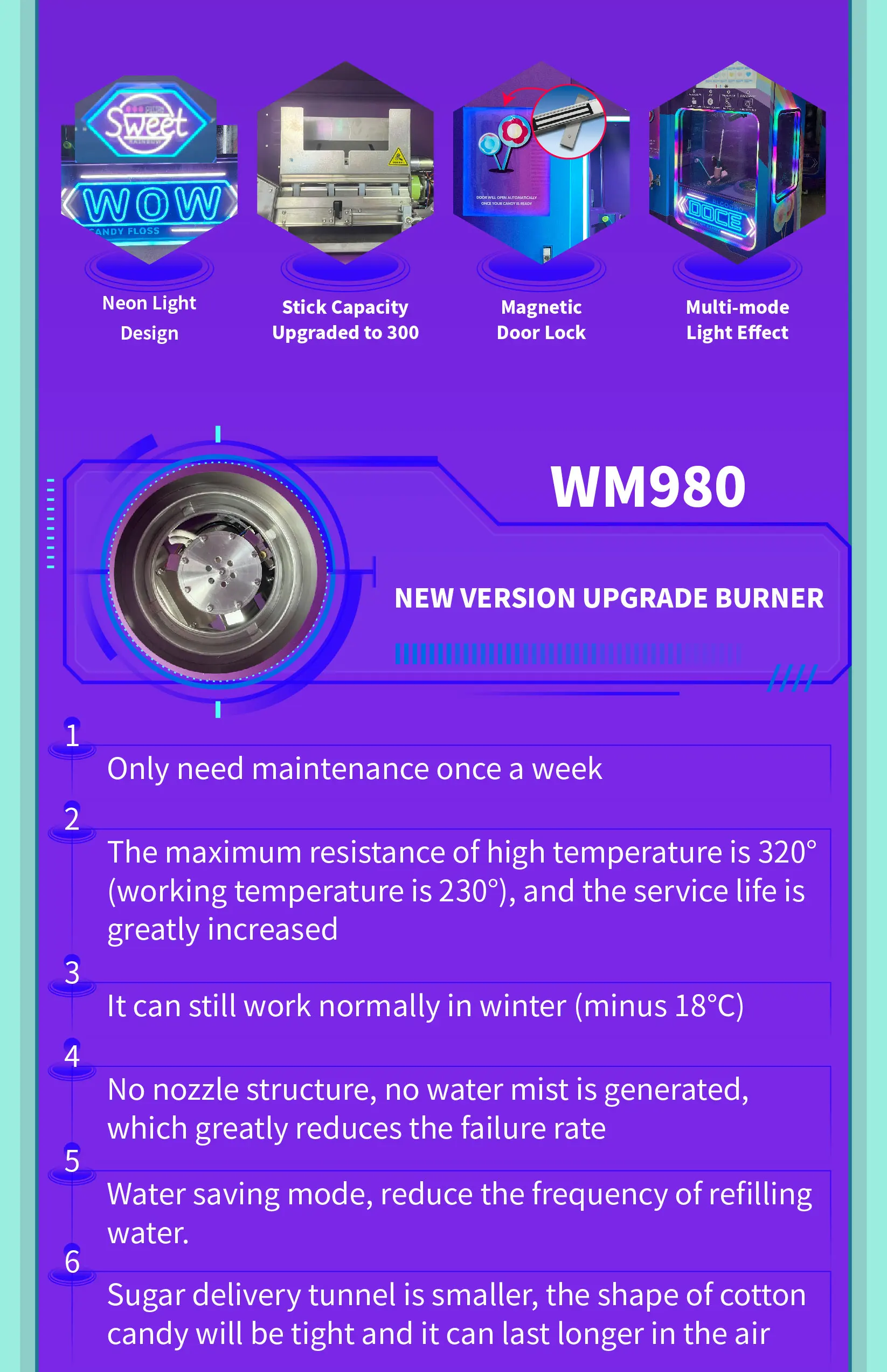

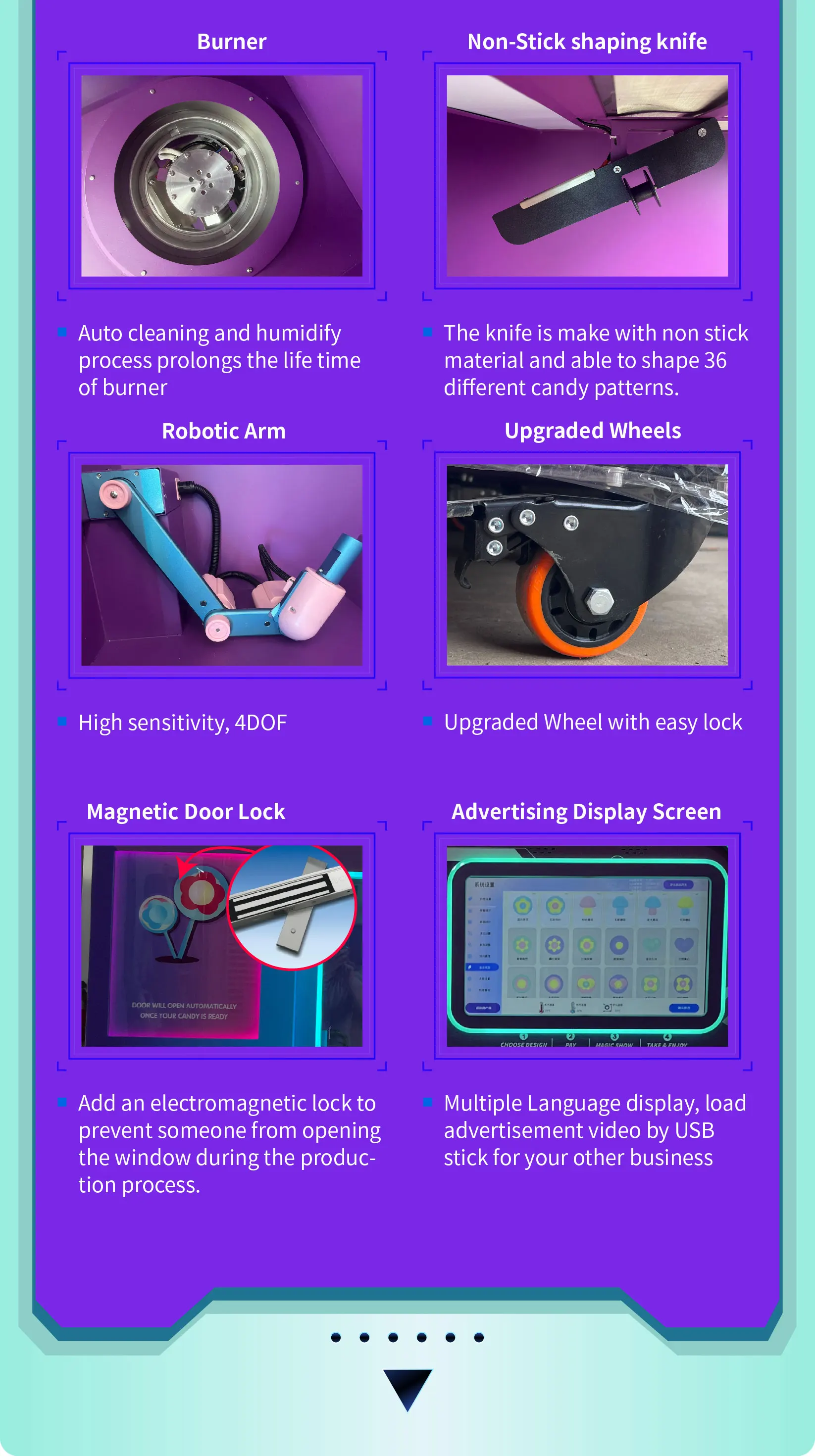

Companies like Wider Matrix, a technology-driven manufacturer with a global footprint, design machines that minimize user error. Their Fully automatic cotton candy vending machine WM980 handles the entire process—preheating, portioning, and spinning—automatically. This eliminates common problems like incorrect preheating and Improper sugar loading, ensuring a perfect product every time and maximizing your potential profit.

Preventative Maintenance Checklist

Keep your machine running smoothly with these simple habits:

- Always use the correct floss sugar.

- Clean the spinner head and bowl immediately after use while still warm.

- Allow the machine to cool completely before storing it.

- Store the machine and sugar in a dry environment to prevent moisture damage.

- Regularly inspect power cords and plugs for damage.

Related Topics

- How Much Can You Make with a Cotton Candy Machine?

- The Ultimate Guide to Cotton Candy Factory Vending Machines

- Phone Case Printing Vending Machine Guide

- Fully Automatic Custom Phone Case Vending Machine

- Is a Cotton Candy Machine a Good Investment?

Conclusion

Diagnosing why your cotton candy machine won’t make cotton candy is usually a process of elimination. Start with the simplest solutions: ensure you’re using the right sugar, that the machine is spotlessly clean, and that it’s fully preheated. Most of the time, this will solve the problem. For persistent or technical issues like heating element or motor failure, you may need to seek professional repair or consider investing in a more robust, commercial-grade machine. For businesses looking to avoid these headaches entirely, automated solutions from experienced manufacturers like Wider Matrix offer reliability and consistency, turning a source of frustration into a seamless, profitable venture. Remember, the sweet success of perfect cotton candy lies in the details of preparation and maintenance.

Specifications

| Model | WM980 |

| Dimensions | 132cm*195cm*67cm |

| Power | 500W when Standby, 3000W when processing |

| Net Weight | 300KG |

| Payment Methods | Coin/Cash/Credit Card/NFC |

| Sugar Consumption | 28~30g per candy |

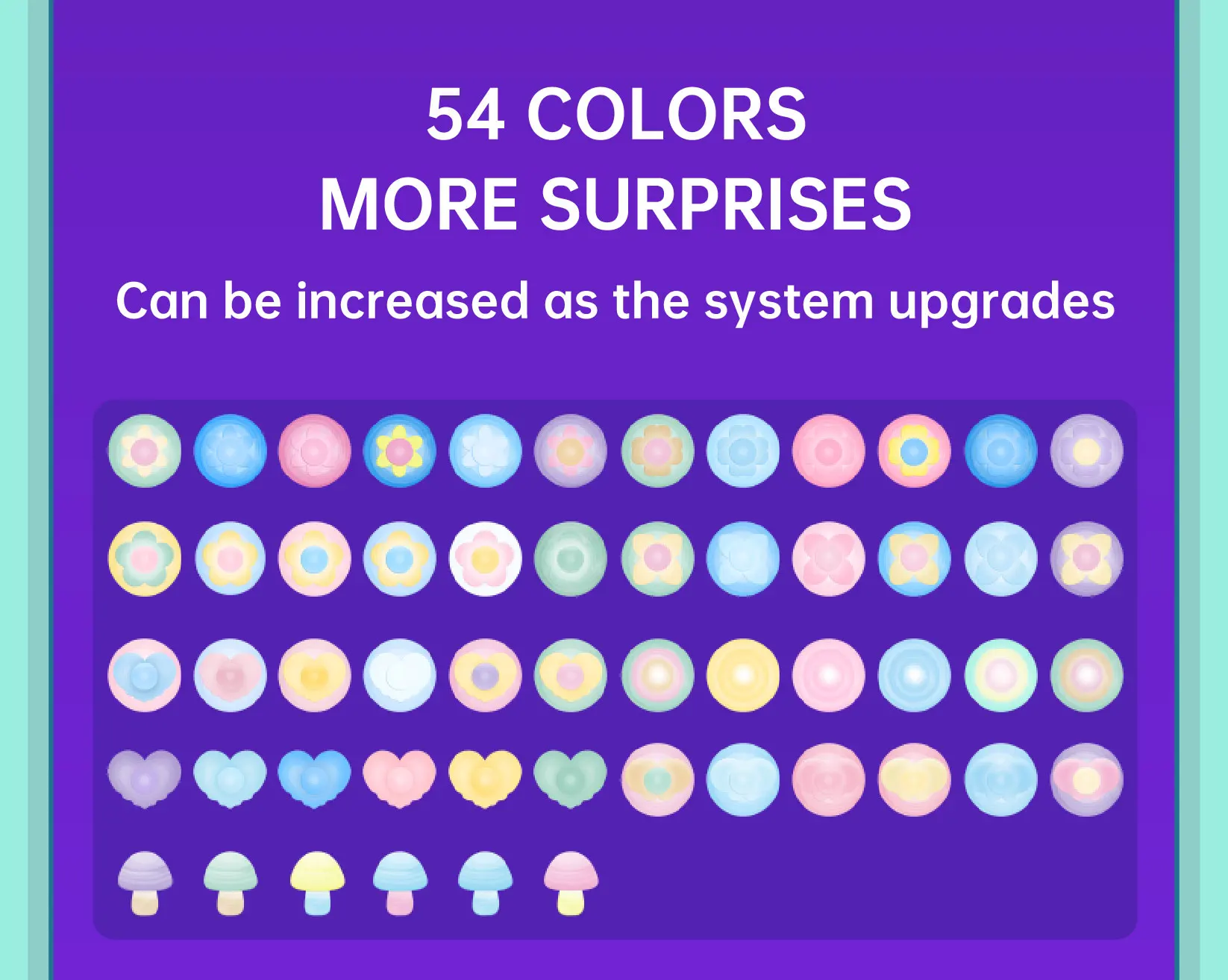

| Cotton Candy Designs | 54 designs and keeping updating |

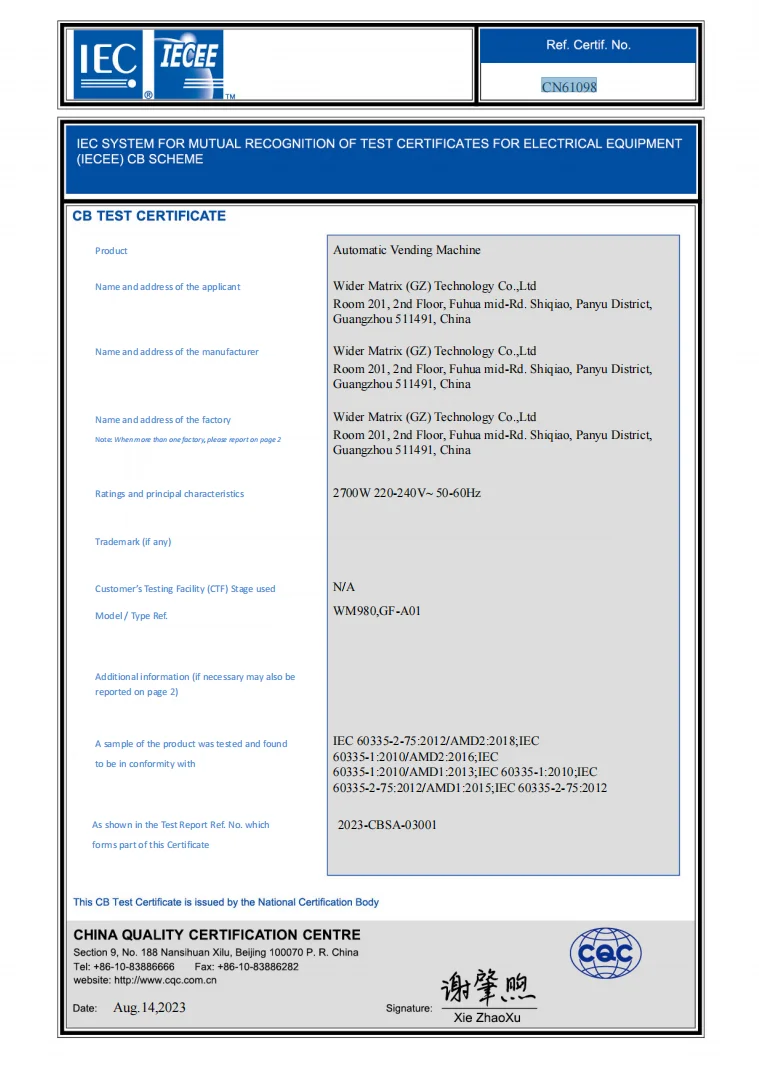

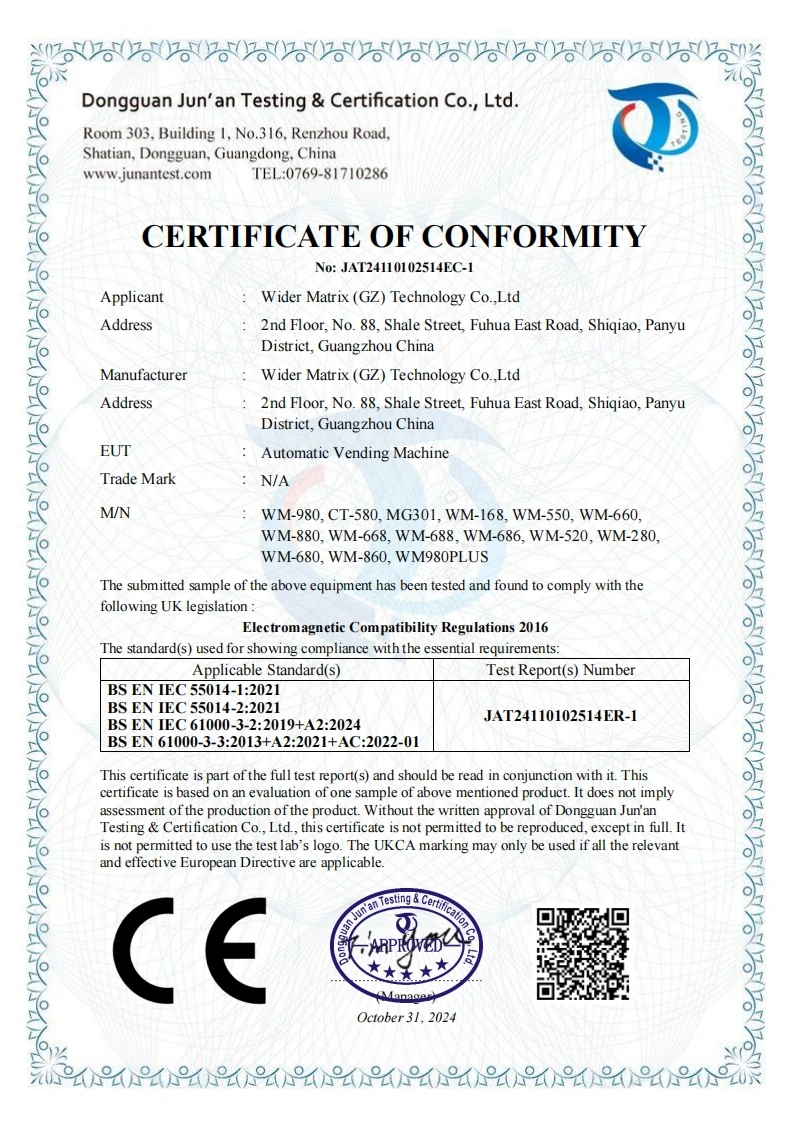

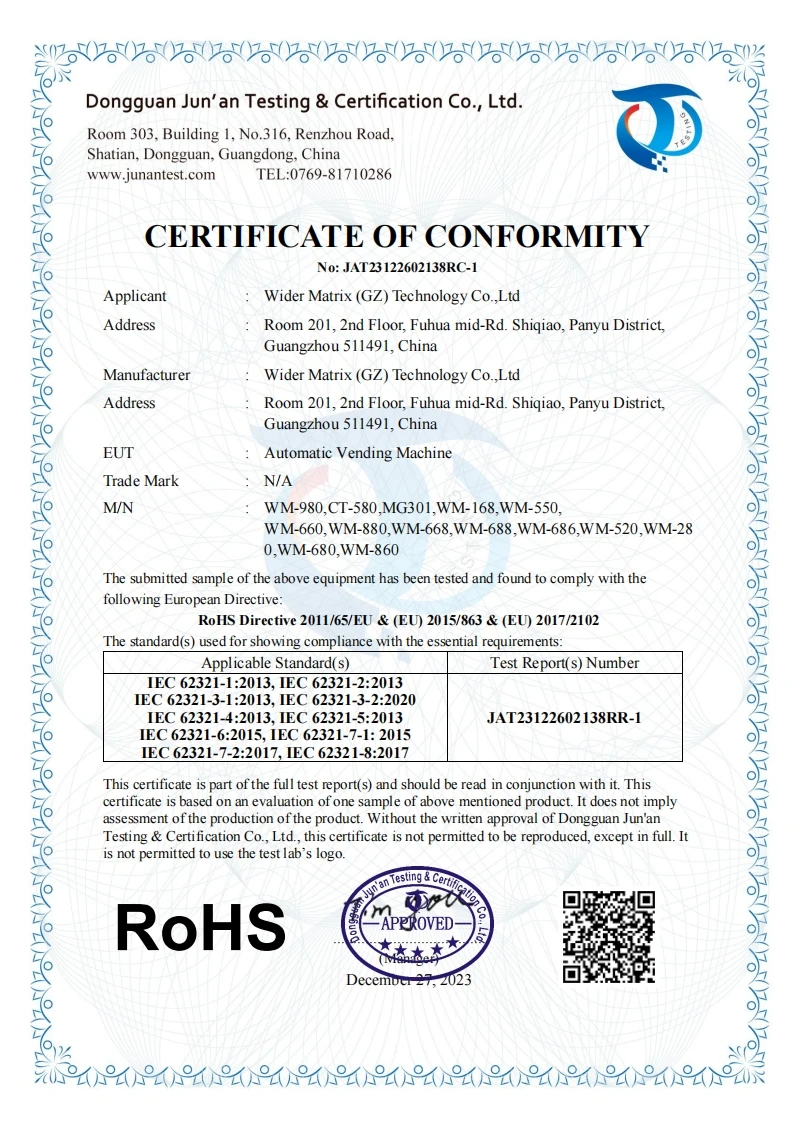

Product Certificates

CE

EN71-1:2014+A1:2018

ASTM

F963-17

FSC

SGS-COC-010200

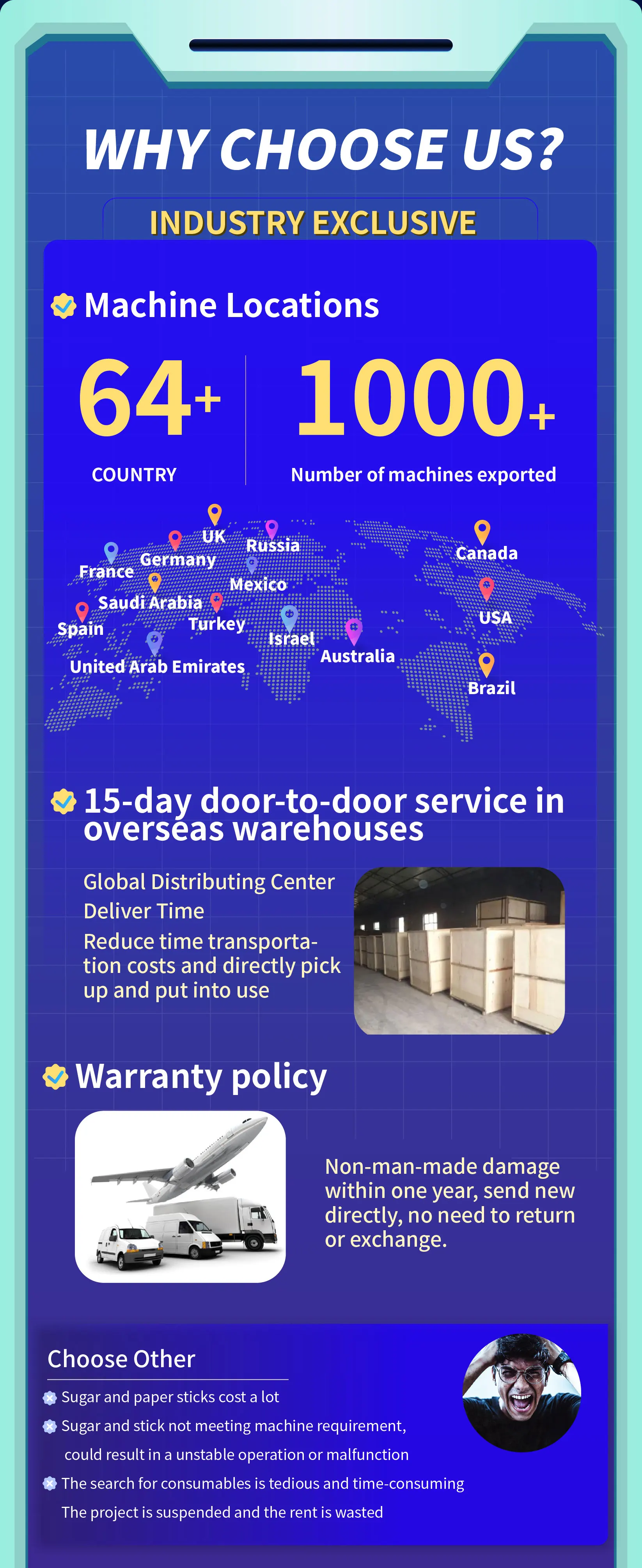

Company Introduction

Wider Matrix (Guangzhou) Technology Co., Ltd. is a scientific and technological enterprise that attaches importance to R&D and user experience. We started to research and develop automated vending solutions in 2016, and achieved a leading position in the field of interactive vending machines.

With years of experience in automated retail technology, we've perfected our puzzle vending machines through rigorous testing and continuous innovation. Our commitment to quality and user experience has allowed us to expand globally, with our products now operating successfully in more than 130 countries including the United States, Canada, throughout Europe, Southeast Asia, Australia, and Israel.

We set up overseas warehouses in the United States, Canada, Britain and Israel to provide customers with consumables and accessories support. All machines support remote cloud management, which has the advantages of easy operation, convenient maintenance and high operating efficiency. After our puzzle vending machines are delivered and put into use, they can bring you considerable benefits.

Every customer's success and satisfaction are the driving force for us to pursue innovation and climb the peak forever. In the future, we will uphold the business philosophy of customer first and quality first, and constantly create more good products for the market. Join us now and start your intelligent and innovative vending machine business!

Exclusive Services

Overseas Support Service

Local transfer warehouse support, ensuring your operational stability.

Custom Design

We offer machine appearance customization, branding, and large-scale custom packaging services.

Initial Tools & Spare Parts Kit

Machine comes with complementary tools and spare parts kit, including initial consumables package for early operations.

Functional Customization & Software Optimization

Custom functionality based on client needs, including hardware and software optimization updates.

Lifetime Technical Support & Updates

We provide lifetime technical support and software update services for all customers.

Frequently Asked Questions

Why is my cotton candy machine smoking?

Smoke is usually caused by old, burnt sugar residue inside the head overheating. It can also occur if sugar is spilled onto the external heating unit. Immediately turn off the machine, let it cool, and perform a deep clean.

Can I use brown sugar or powdered sugar?

No. Brown sugar contains molasses, which burns easily and creates a sticky mess. Powdered sugar contains cornstarch, which will not spin and can clog your machine. Only use pure, coarse floss sugar designed for cotton candy makers.The head is spinning but no cotton candy is forming. Why?

This almost always points to a heating issue. The head is spinning, but it's not hot enough to melt the sugar. Check that the machine is fully preheated and that the heating element is functioning.My cotton candy is too wet and sticky. What did I do wrong?

Sticky cotton candy is typically a result of high humidity in the air or adding too much sugar at once, which cools down the head. Try making cotton candy in a less humid environment and add sugar in small, steady amounts.How do I know if my heating element is broken?

If the machine has been on for 10-15 minutes and the head is not hot to the touch (be very careful!), the heating element may have failed. You may also notice that sugar just piles up and melts into a syrup instead of spinning into threads.Are Wider Matrix's automatic cotton candy machines easier to maintain than traditional models?

Yes, that's a key design focus. Wider Matrix's WM980 model features a automated cleaning function that reduces residue buildup. Their machines are built with commercial-grade components designed for high-volume use and easier maintenance, addressing many of the common failure points found in cheaper, consumer-grade units. This makes them a potentially excellent investment for serious vendors.Why is my cotton candy brown?

Brown cotton candy means the sugar is burning. This is often due to the head being too hot. If your machine has a temperature control, turn it down. It can also be caused by using the wrong type of sugar that contains impurities.Customer Reviews

The cotton candy vending machine from Widermatrix has been an incredible addition to our theme park. Visitors are amazed by the automated process and variety of designs. The machine operates flawlessly even during peak hours, and the cloud management system makes monitoring and maintenance incredibly simple.

I installed three cotton candy machines in my shopping malls, and they've been running perfectly for over four months. The 54 different candy designs are a huge hit with customers of all ages. Sugar consumption is exactly as advertised, and the remote monitoring system allows me to check inventory levels without visiting each location.

As a first-time business owner, the cotton candy vending machine has exceeded my expectations. The colorful designs attract crowds at my family entertainment center, and children are mesmerized watching the automated process. The payment system accepts all methods as advertised, and technical support has been outstanding whenever I've had questions.

The cotton candy vending machine has revolutionized our carnival business. Setup was straightforward, and the machine began generating profits from day one. The power consumption is exactly as specified, and the machine handles high-volume periods without any issues. The variety of candy designs keeps customers coming back to try new patterns. Perfect investment for event businesses.

Our cotton candy vending machine achieved ROI within just five months! The 300kg machine is surprisingly easy to maintain despite heavy daily use. We love how the machine creates perfect cotton candy designs consistently, and our customers are always delighted by the experience. The technical team responds quickly whenever we need assistance with new features.

I operate several food courts and decided to add cotton candy machines to diversify offerings. The WM980 model has been phenomenal - customers are fascinated by the automated process and unique designs. The branding customization option allowed us to match our corporate identity perfectly. The machines have become such attractions that we've ordered five more for our newest locations.

Excellent cotton candy machine, though installation took longer than expected due to its size (132cm*195cm*67cm). Once operational, performance has been outstanding. The 54 different candy designs are a huge hit with our customers. Sugar consumption is efficient at 28-30g per candy. Technical support was very responsive when we needed help configuring the payment system.

Our university cafeteria installed this cotton candy machine six months ago, and it's been a massive success. Students are fascinated by the automated process and artistic designs. Even during rush periods, the machine handles high demand without issues. The power efficiency is impressive - only 500W on standby as advertised. The cloud management system makes inventory tracking and maintenance scheduling incredibly simple.

As the owner of a candy store chain, adding this cotton candy machine was the best decision I've made. It's become the centerpiece attraction in our flagship store. The machine creates beautiful cotton candy art that customers photograph and share on social media, bringing in new customers daily. The multiple payment options (Coin/Cash/Credit Card/NFC) accommodate all customer preferences. Worth every penny!

Our airport lounge installed the WM980 cotton candy machine eight months ago, and it's been operating flawlessly 24/7. Travelers are delighted by the unexpected treat, especially families with children during long layovers. The machine's reliability is impressive - zero downtime despite constant use. The remote monitoring system allows our staff to check sugar levels and maintenance needs without interrupting service. A perfect addition to our premium lounge experience.

rapid response

Interested in the product? Fill out the form now to get more information.