Who Manufactures iPhone Cases? A Deep Dive into the Global Supply Chain

Service Support

- ✓ Support for small batch customization

- ✓ Fast delivery worldwide

- ✓ 12-month warranty service

- ✓ Online technical support

When you slip a protective case onto your iPhone, have you ever wondered about its journey? The question “Who manufactures iPhone cases?” opens a window into a vast and complex global industry. From tech giants’ official partners to countless third-party suppliers, the ecosystem is diverse. This comprehensive guide not only lists key players but also explores manufacturing hubs, business models, and how innovation from companies like Wider Matrix is revolutionizing how we access these essential accessories.

The Top iPhone Case Manufacturers: A Global Overview

The market is segmented between manufacturers that supply Apple directly (or are part of its authorized network) and the enormous third-party market that caters to every conceivable style and budget.

1. Apple’s Official Partners and Contract Manufacturers

While Apple designs its own first-party cases (like the Silicone or Clear Case), it contracts the manufacturing to specialized firms, primarily in Asia. These partners must meet exceptionally high standards for quality, materials, and labor practices.

- Foxconn (Hon Hai Precision Industry Co., Ltd.): A Taiwanese multinational and Apple’s most famous assembly partner. While known for assembling iPhones, it also has divisions that manufacture accessories, including cases.

- Pegatron: Another key Taiwanese electronics manufacturer that assembles Apple devices and likely produces accessories as part of its contract manufacturing services.

- Luxshare-ICT: A rising Chinese company that has become a significant supplier to Apple, involved in the assembly of various products and potentially accessories.

2. Leading Third-Party iPhone Case Manufacturers

This segment is where most brands you recognize operate. They design and market cases but outsource production to OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) factories.

- OtterBox: A US-based brand known for its rugged, high-protection cases. Their cases are manufactured in various global locations, including China and Mexico.

- Spigen: A South Korean brand that designs its cases and manufactures them through partner factories in China and South Korea.

- Case-Mate: Specializes in fashion-oriented cases, partnering with manufacturers to produce their designs.

- Incipio: Another major US brand that relies on a global supply chain, primarily in Asia, for manufacturing.

Global Manufacturing Hubs: Where Are iPhone Cases Made?

The vast majority of iPhone cases, whether for Apple or third-party brands, are manufactured in Asia. This is due to established supply chains, technical expertise, and cost efficiencies.

| Region/Country | Key Characteristics | Known For |

|---|---|---|

| Southern China (Guangdong, Shenzhen) | The world’s epicenter for electronics manufacturing. Home to countless OEM/ODM factories. | High-volume production, prototyping, all case types (silicone, TPU, polycarbonate). |

| India | A growing hub fueled by government incentives (“Make in India”) and Apple’s supply chain diversification. | Increasing production for both domestic market and export, often by Apple’s partners like Foxconn. |

| United States & Europe | Smaller, niche segment focused on premium, customized, or “locally made” products. | Low-volume, high-margin cases (e.g., premium leather, custom designs). |

Beyond Traditional Manufacturing: The Rise of On-Demand Production

The industry is evolving from mass production in distant factories to instant, localized customization. This is where technology innovators like Wider Matrix are changing the game. Instead of waiting for shipments from large-scale manufacturers, businesses can now offer instantly personalized cases directly to consumers.

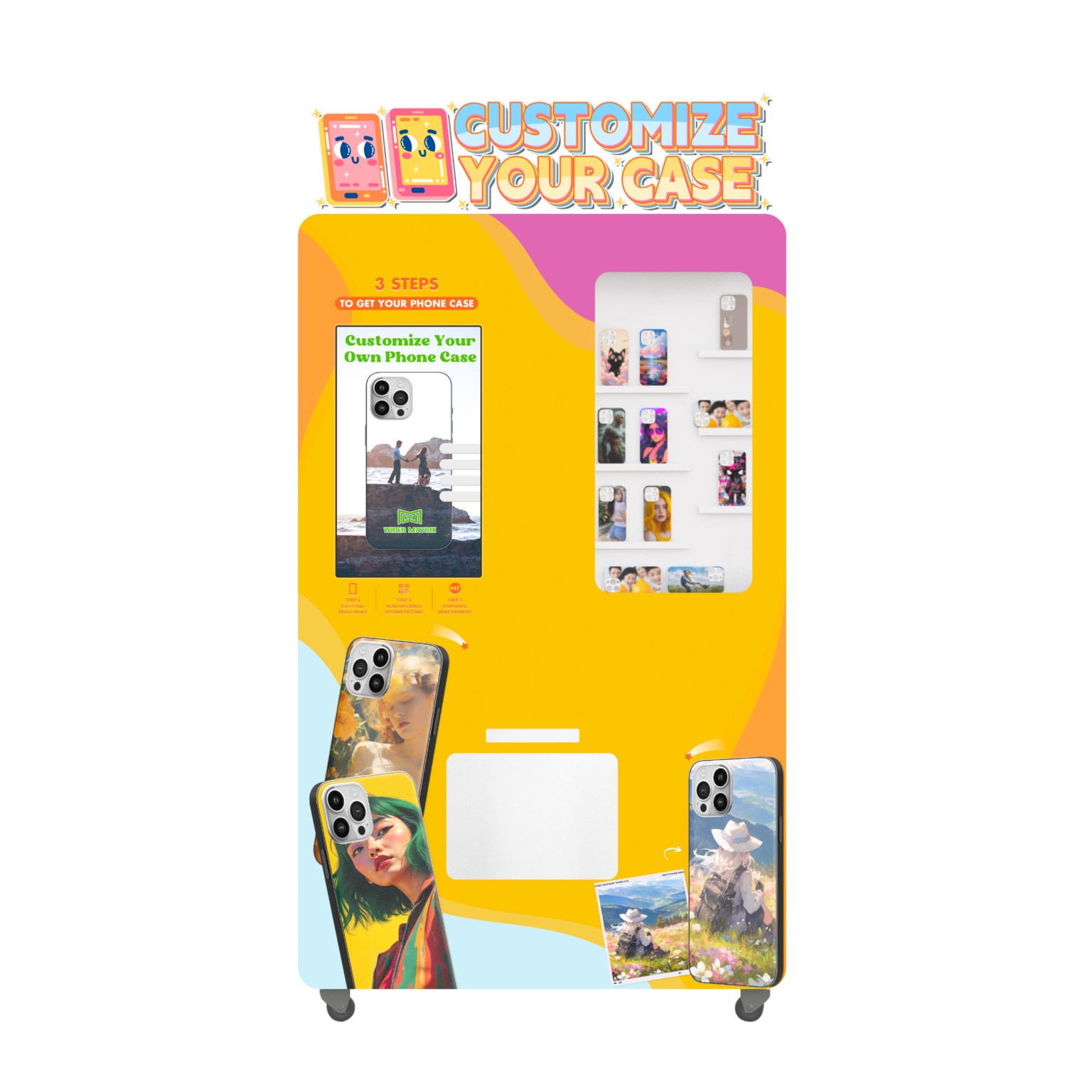

Wider Matrix is at the forefront of this shift with its advanced iPhone case vending machines. These automated kiosks allow users to select and print a custom-designed case on the spot, answering the question of “who manufactures it” with “the machine right in front of you.” This model demonstrates how profitable selling phone cases can be with reduced inventory risk and immediate customer engagement. For those interested in the machinery behind this, our guide on what machine you need to print phone cases provides a detailed breakdown.

How to Choose an iPhone Case Manufacturer for Your Business

If you’re looking to source or brand iPhone cases, your choice depends on your business model.

- For Large Volume/Private Label: Partner with established OEMs in Shenzhen, China. Attend trade shows like Canton Fair or leverage platforms like Alibaba to find verified suppliers.

- For Small Batch/Customization: Seek out smaller factories or print-on-demand services that cater to entrepreneurs.

- For Instant Retail/Point-of-Sale: Consider innovative solutions like vending machines that make the most money, such as Wider Matrix’s automated kiosks. This eliminates the need for traditional manufacturing partnerships altogether, offering a turnkey solution. Explore the potential with our DIY phone case vending startup guide.

Related Topics

- How Profitable Is Selling Phone Cases? A 2025 Business Analysis

- What is the Most Profitable Vending Machine to Own in 2025?

- Who is the Best Jigsaw Puzzle Maker?

- How to Find a Location to Put a Vending Machine: The Ultimate Guide

- 15 units shipped to France!

Conclusion

The answer to “Who manufactures iPhone cases?” is multi-faceted, involving global giants like Foxconn, specialized third-party brands, and countless factories in Asia. However, the future of manufacturing is not just about who makes the cases, but how and where they are made. The industry is embracing agility and personalization. Wider Matrix exemplifies this shift, moving manufacturing from faraway factories directly into shopping malls and retail spaces with its innovative vending solutions. Whether you’re a consumer curious about your case’s origins or an entrepreneur looking to enter the market, understanding this ecosystem is key to recognizing the value and technology behind every iPhone case.

Specifications

| Model | WM880 |

| Device Dimensions | 128cm*87cm*230cm |

| Device Weight | 220KG |

| Power | 220W |

| Voltage | 220V/110V (Optional) |

| Payment Methods Supported | Coin/Cash/Credit Card/NFC/WeChat/Alipay |

| Printing Technology | 6-color UV printing |

| Printing Resolution | 1440DPI |

| Printing Speed | 2-3 minutes/piece |

| Supported Phone Models | 96 mainstream models |

| Phone Case Storage Capacity | 300-500 pieces |

| Display Screen | 27-inch touch display, supports video ad rotation |

| Remote Management | Supports cloud monitoring and management |

Product Certificates

CB

CN61098

UKCA

JAT24110102514136

RoHS

JAT23122602137123

Company Introduction

Wider Matrix (Guangzhou) Technology Co., Ltd. is a scientific and technological enterprise that attaches importance to R&D and user experience, We started to research and develop vending machines in 2016, and achieved a leading position in the field of unattended vending machines.

In 2019, we manufactured the first automatic cotton candy vending machine. After testing in domestic market, refining our product for years, fixing the issues you might run into while operating, the performance of our machines are stable enough and reach the standard for export finally. Till now, our machine has been exported to more than 130 countries such as the United States,Canada,Europe, Southeast Asia, Australia and Israel.

We set up overseas warehouses in the United States, Canada, Britain and Israel to provide customers with consumables and accessories support. All machines support remote control, which has the advantages of easy operation, convenient maintenance and high operating efficiency. After our cotton candy vending machines are delivered and put into use, they can bring you considerable benefits.

Every customer's success and satisfaction are the driving force for us to pursue innovation and climb the peak forever. In the future, we will uphold the business philosophy of customer first and quality first, and constantly create more good products for the market. Join us now and start your intelligent and innovative vending machine business!

Exclusive Services

Overseas Support Service

Local transfer warehouse support, ensuring your operational stability.

Custom Design

We offer machine appearance customization, branding, and large-scale custom packaging services.

Initial Tools & Spare Parts Kit

Machine comes with complementary tools and spare parts kit, including initial consumables package for early operations.

Functional Customization & Software Optimization

Custom functionality based on client needs, including hardware and software optimization updates.

Lifetime Technical Support & Updates

We provide lifetime technical support and software update services for all customers.

Frequently Asked Questions

Who is the largest manufacturer of iPhone cases?

There is no single "largest" manufacturer. Foxconn is arguably the largest contract manufacturer involved in Apple's official supply chain, while countless OEM factories in China produce the bulk of third-party cases for global brands.

Are all iPhone cases made in China?

While the overwhelming majority are manufactured in China due to its concentrated supply chain, production is diversifying. India is becoming a significant hub, and there are small-batch, premium case makers in the USA and Europe.What materials are most iPhone cases made from?

The most common materials are Thermoplastic Polyurethane (TPU) for flexible cases, Polycarbonate (PC) for hard shells, and combinations of both (hybrid cases). Other materials include silicone, leather, metal, and sustainable alternatives like recycled plastics.How can I get into the iPhone case business with a low upfront investment?

Instead of investing in large inventory from a manufacturer, a low-risk model is using print-on-demand services or operating a vending kiosk. Companies like Wider Matrix provide vending machines that handle the manufacturing and sales process in one place, significantly lowering the barrier to entry.What is the difference between an OEM and an ODM manufacturer?

An OEM (Original Equipment Manufacturer) produces cases based on your designs and specifications. An ODM (Original Design Manufacturer) designs and manufactures the cases itself; you simply add your brand logo to their existing products. ODMs offer less uniqueness but are easier and faster to work with.How does Wider Matrix's vending solution compare to traditional manufacturing?

Traditional manufacturing is ideal for mass-producing a single design. Wider Matrix's vending technology (conceptually similar to their other machines) focuses on micro-manufacturing. It allows for ultimate customization, zero inventory waste, and immediate revenue at the point of sale, making it a complementary, modern approach to the industry.User Reviews

Widermatrix has been so great to work with especially Taylor. Taylor sends pictures and testimonials and data to help the decision process. Once decided the process is smooth and Taylor sends updates with pictures and videos of YOUR phone case vending machine along the way. Once it arrived the 24 hr tech support was patient with me as we worked hard to get it all dialed in. The claims are real, this automated phone case dispenser is half paid back on my initial invest just after 2 months! Kids and adults love these protective case kiosks.

I bought two phone case vending machines, and they have been in operation for over three months and are very stable. The smartphone accessory kiosks have excellent reliability and require minimal maintenance.

This is my first time running a phone case vending machine business and it looks great. The automatic mobile accessory dispenser attracts many customers in my shopping mall location.

rapid response

Interested in the product? Fill out the form now to get more information.