Why Is My Cotton Candy Machine Spitting Out Sugar? Troubleshooting Guide

Service Support

- ✓ Support for small batch customization

- ✓ Fast delivery worldwide

- ✓ 12-month warranty service

- ✓ Online technical support

Few things are more frustrating than setting up your cotton candy machine, only to have it spit out sugar instead of producing fluffy, delicious cotton candy. This common issue can stem from several factors, ranging from incorrect sugar type to improper machine maintenance. In this comprehensive guide, we’ll explore the reasons behind this problem and provide practical solutions to get your machine working perfectly again.

Common Reasons Your Cotton Candy Machine Spits Out Sugar

1. Using the Wrong Type of Sugar

Not all sugars are created equal when it comes to cotton candy production. Regular granulated sugar is often too coarse for most home cotton candy machines to properly melt and spin into threads.

The ideal sugar for cotton candy machines should be:

- Extra fine granulated sugar

- Specialty cotton candy sugar (often called “floss sugar”)

- Sugar mixed with flossine (a commercial additive that improves texture)

2. Temperature Issues

If your machine isn’t reaching the proper temperature (typically between 320-350°F or 160-175°C), the sugar won’t melt correctly. This can cause it to simply spit out rather than form proper threads.

3. Dirty or Clogged Machine Components

Residue buildup from previous use can prevent proper sugar melting and spinning. Key areas to check and clean include:

- The spinning head

- Heating element

- Any screens or filters

- The sugar reservoir

4. Improper Loading Technique

How you add sugar to the machine matters. Common mistakes include:

- Adding too much sugar at once

- Pouring sugar too quickly

- Not allowing the machine to fully preheat

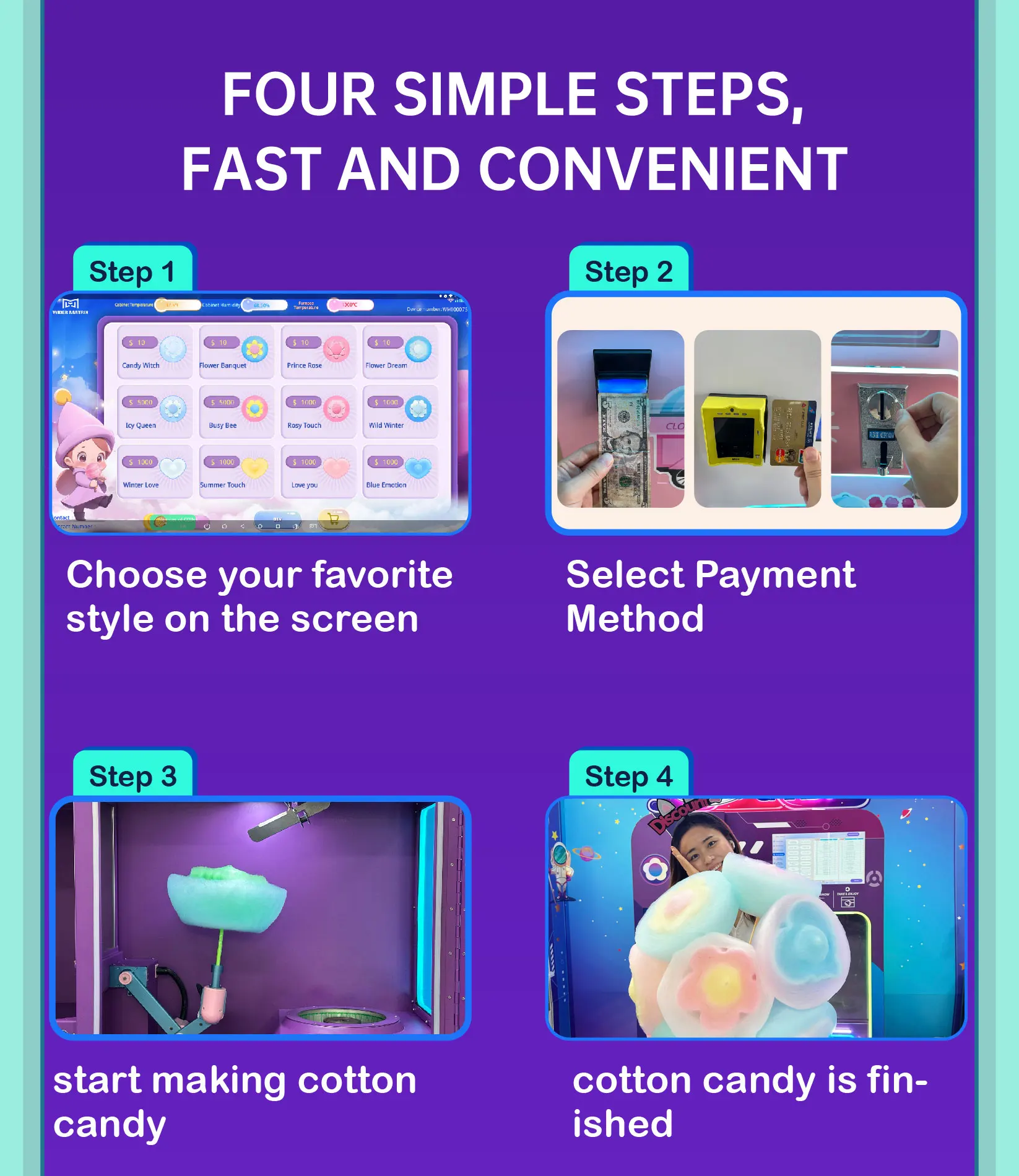

Step-by-Step Troubleshooting Guide

Step 1: Verify Your Sugar Type

Check that you’re using the right sugar. If using regular granulated sugar, try:

- Pulsing it in a food processor to make it finer

- Mixing it with a small amount of corn syrup (about 1 tsp per cup of sugar)

- Purchasing specialty cotton candy sugar

Step 2: Check Temperature Settings

Ensure your machine is properly preheated and maintaining adequate temperature:

- Allow 5-10 minutes for full preheating

- Check manufacturer’s recommended temperature settings

- Test with an infrared thermometer if possible

Step 3: Thorough Cleaning

A deep clean can often solve spitting issues:

- Unplug and cool the machine completely

- Disassemble removable parts according to manufacturer instructions

- Use warm water and mild detergent to clean all components

- Remove any burnt sugar residue with a soft brush

- Dry all parts thoroughly before reassembly

When to Consider Professional Help or Replacement

If you’ve tried all troubleshooting steps and your machine still spits sugar, it might indicate:

- A faulty heating element

- Motor issues

- Other internal component failures

For businesses experiencing frequent issues with traditional cotton candy machines, upgrading to a fully automatic cotton candy vending machine from Wider Matrix might be a more reliable solution. These commercial-grade machines are designed for continuous operation with minimal maintenance.

Preventive Maintenance Tips

To avoid future issues with your cotton candy machine:

- Clean after every use

- Store in a dry, dust-free environment

- Use only recommended sugar types

- Inspect regularly for wear and tear

- Follow manufacturer’s maintenance schedule

Related Topics

- How Much Can You Make with a Cotton Candy Machine?

- Is a Cotton Candy Machine a Good Investment?

- The Ultimate Guide to Cotton Candy Vending Machines

- Different Types of Vending Machines

- About Wider Matrix Technology

Conclusion

A cotton candy machine spitting out sugar instead of producing fluffy treats is a common but solvable problem. By understanding the potential causes – from sugar type to machine maintenance – you can quickly get your machine back to optimal performance. For businesses looking for more reliable solutions, Wider Matrix offers commercial-grade vending machines designed to minimize these common issues while maximizing production efficiency and profitability. Whether you’re troubleshooting a home machine or considering a commercial solution, proper understanding and maintenance are key to sweet success.

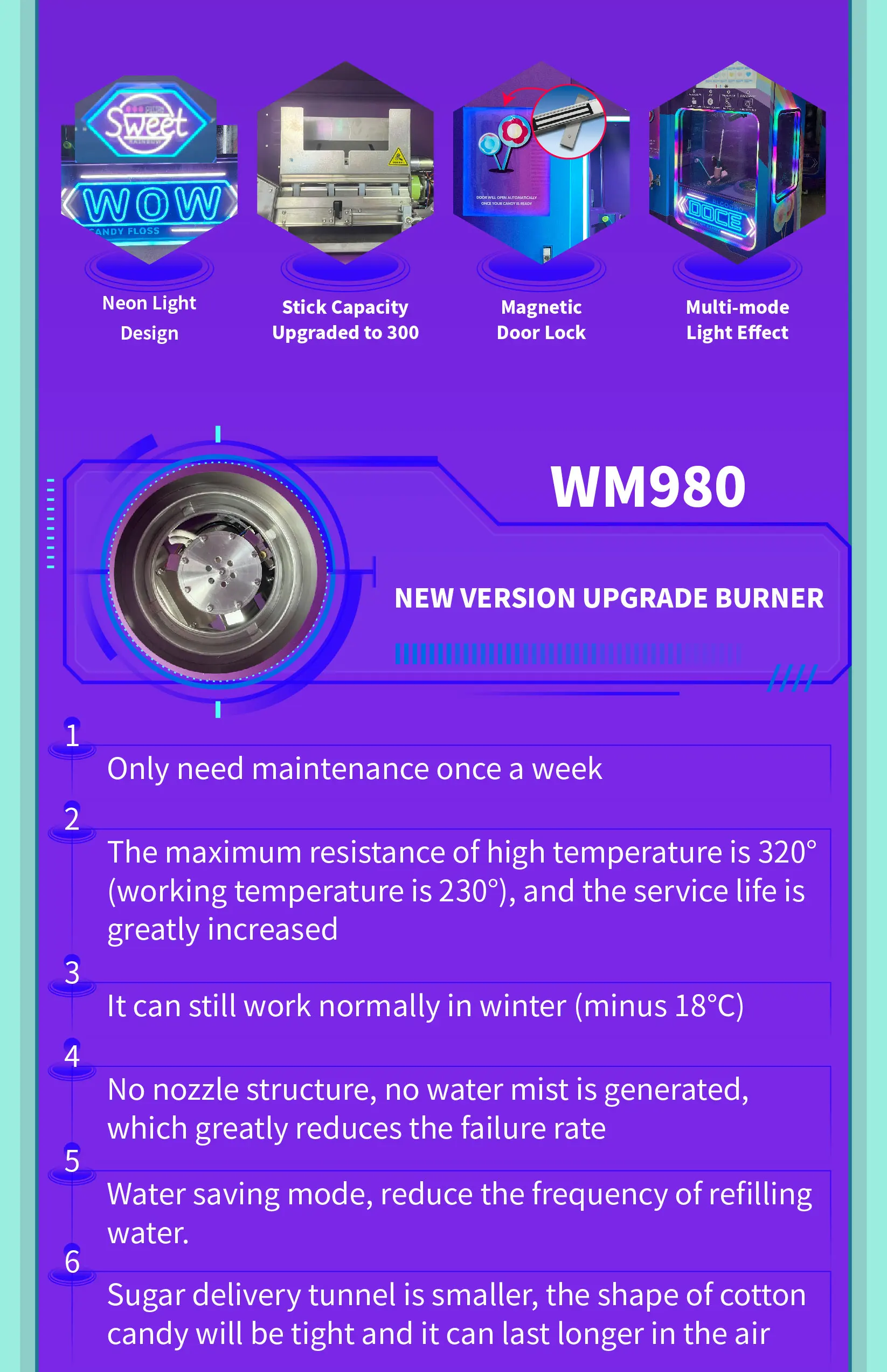

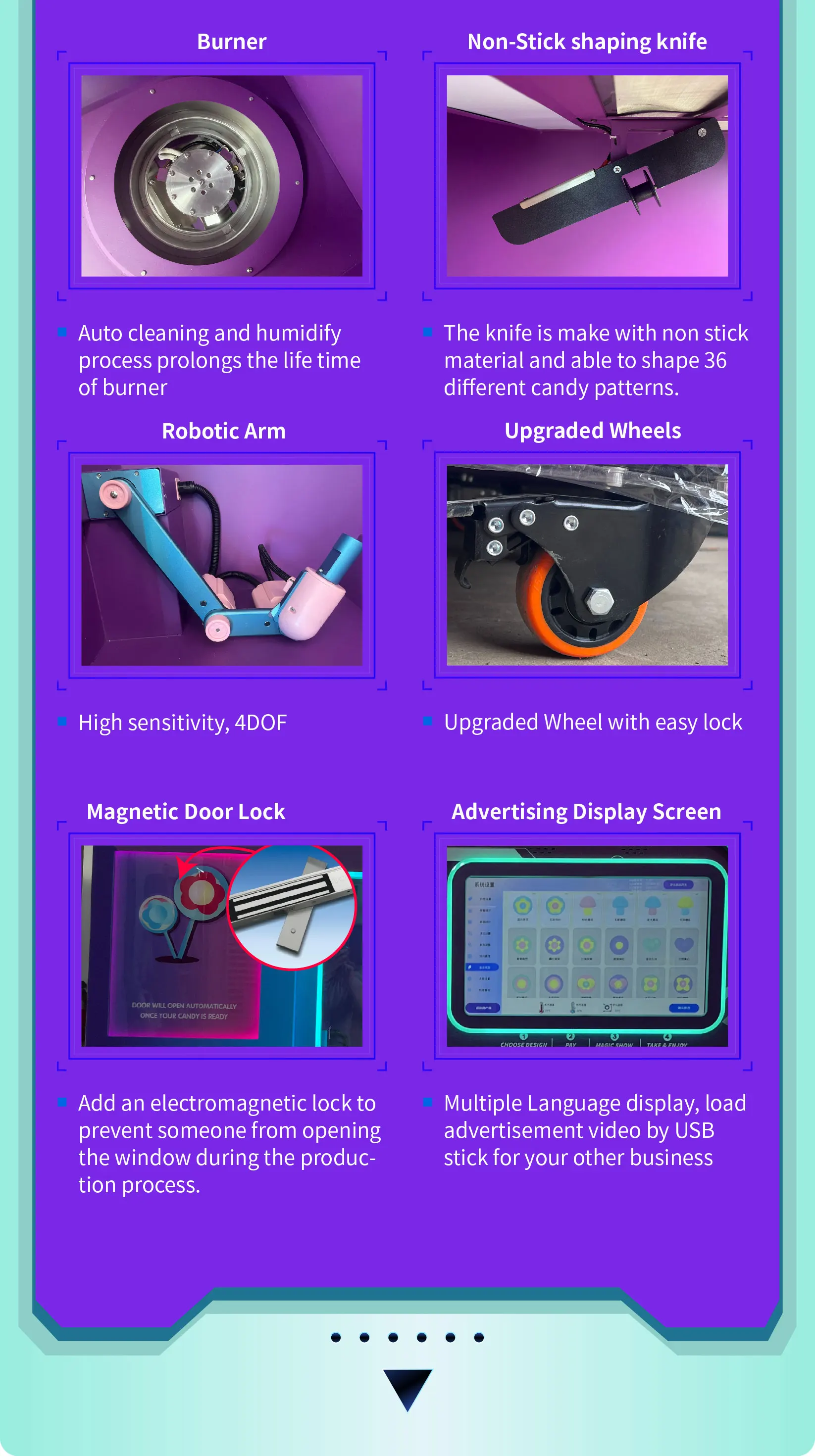

Specifications

| Model | WM980 |

| Dimensions | 132cm*195cm*67cm |

| Power | 500W when Standby, 3000W when processing |

| Net Weight | 300KG |

| Payment Methods | Coin/Cash/Credit Card/NFC |

| Sugar Consumption | 28~30g per candy |

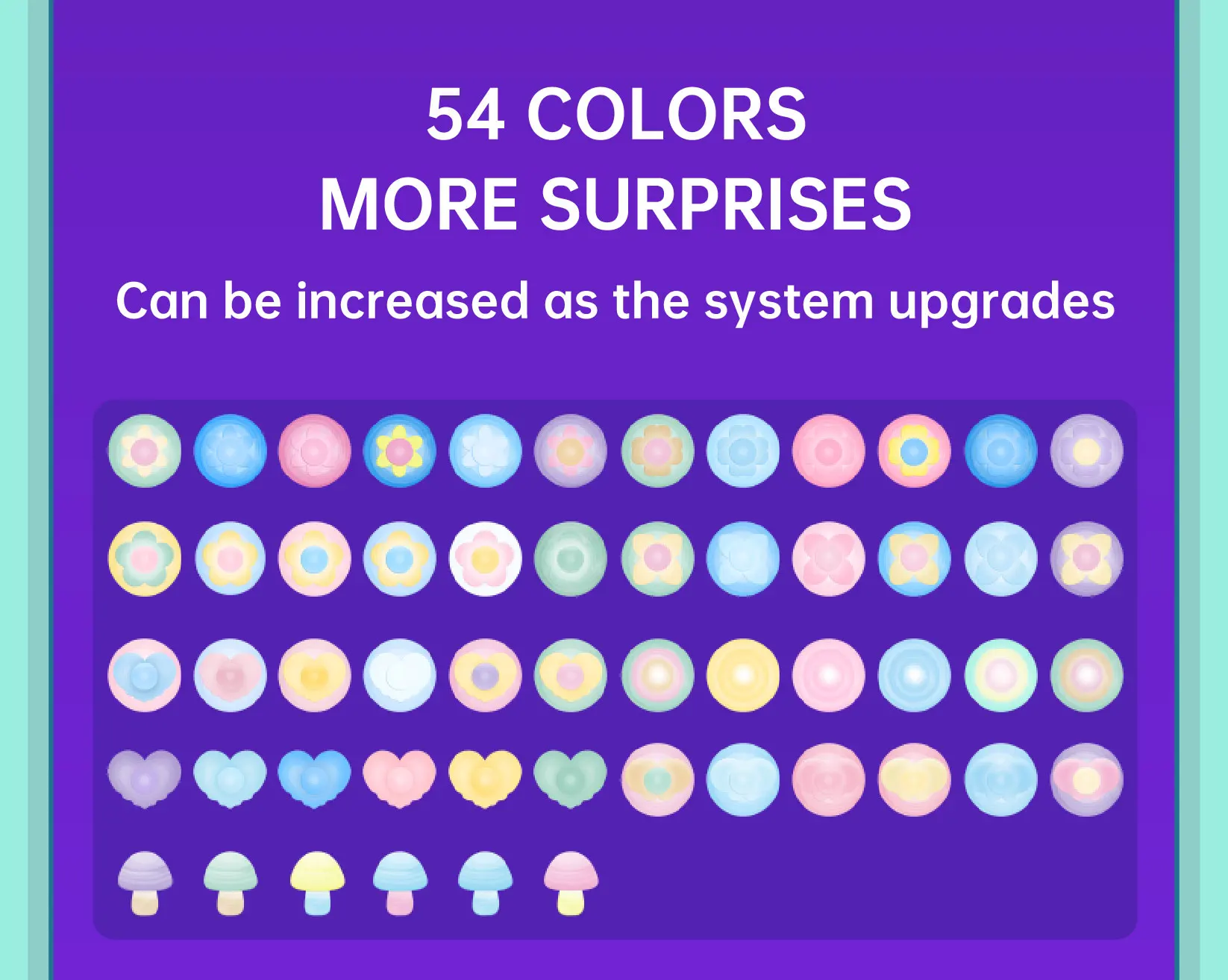

| Cotton Candy Designs | 54 designs and keeping updating |

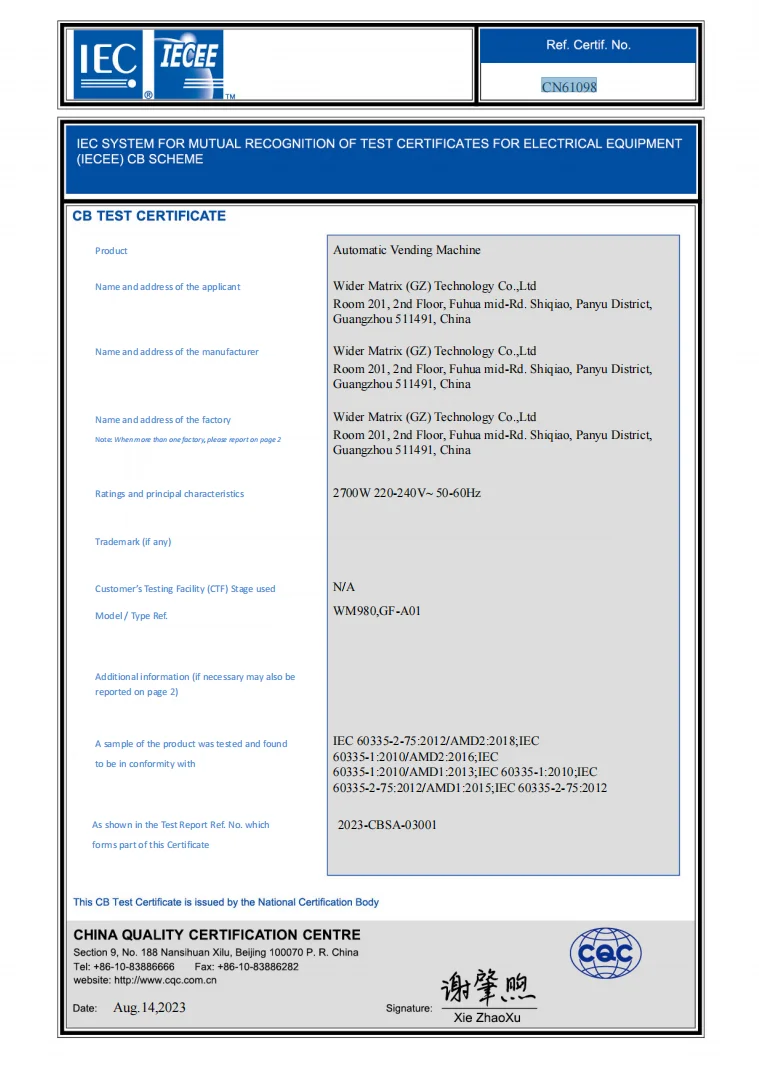

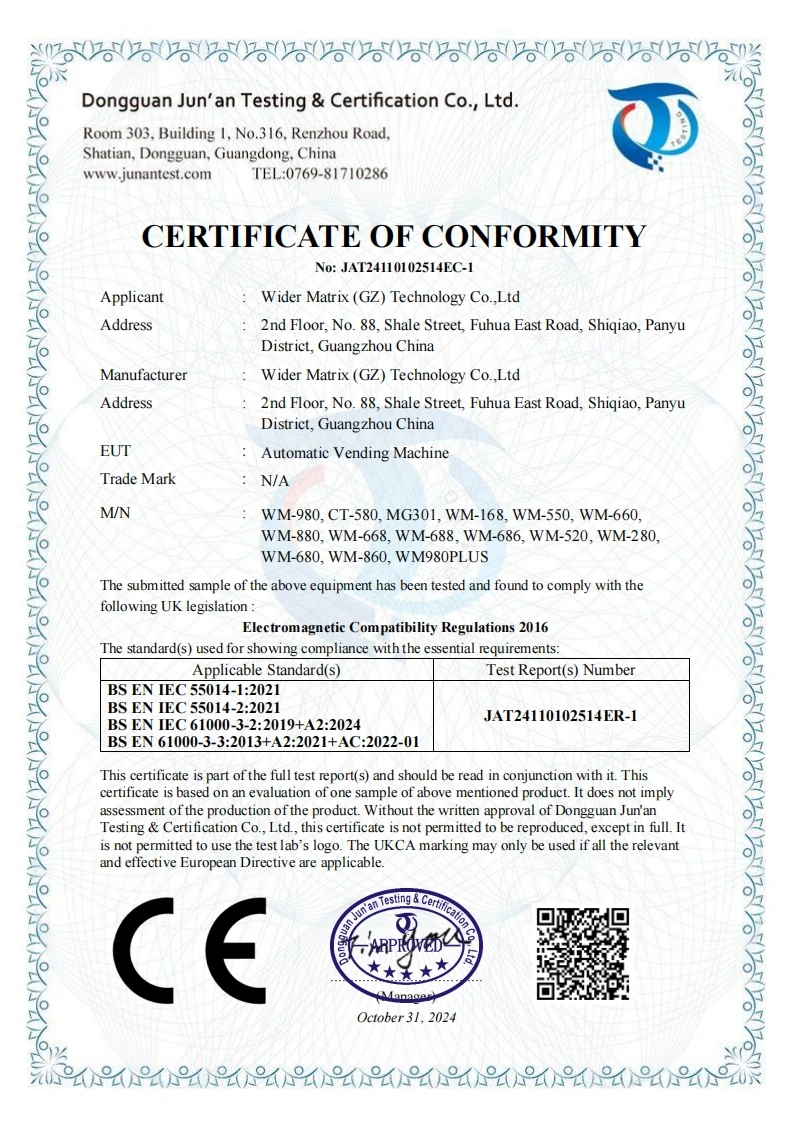

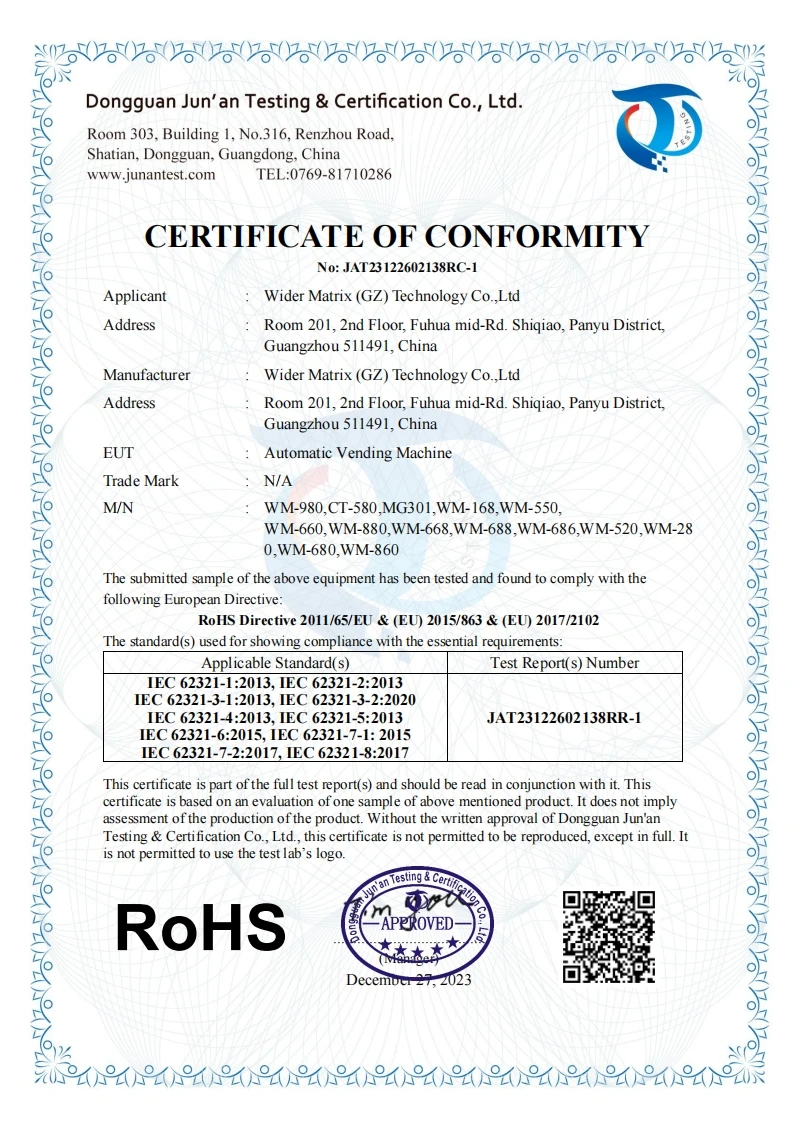

Product Certificates

CE

EN71-1:2014+A1:2018

ASTM

F963-17

FSC

SGS-COC-010200

Company Introduction

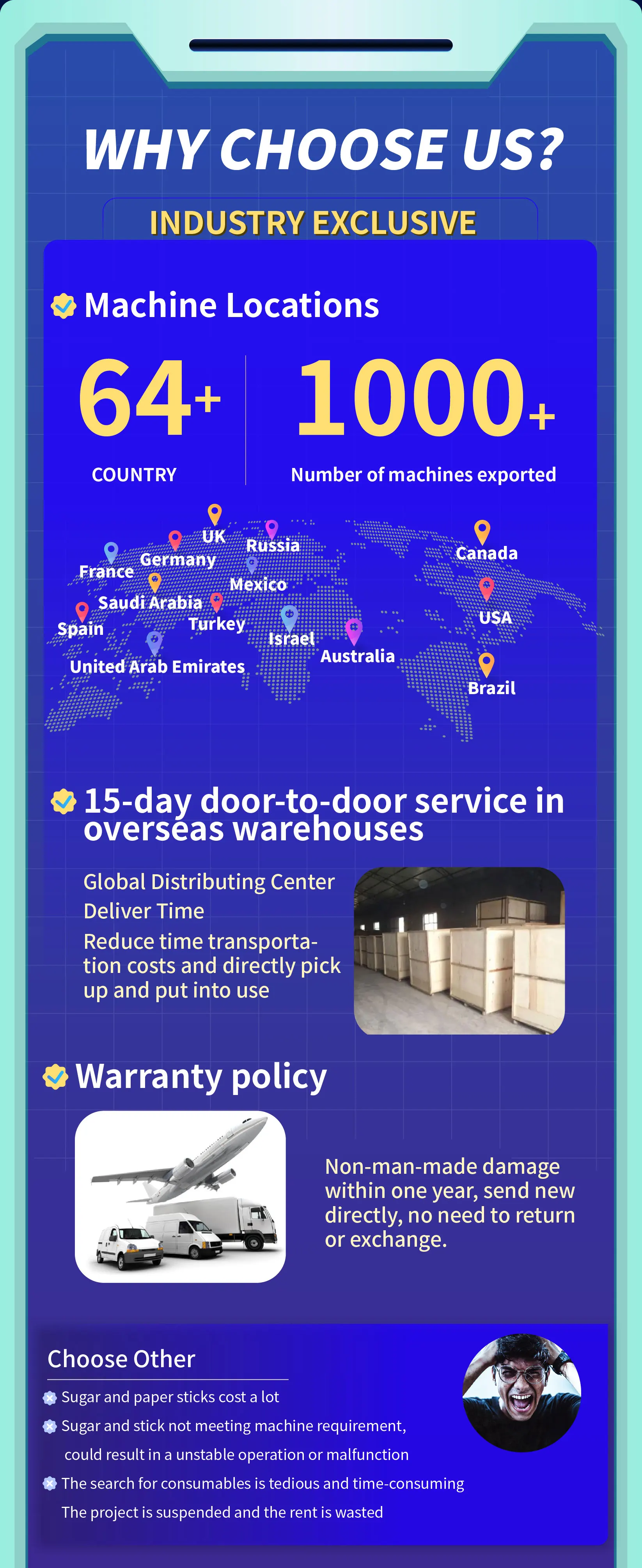

Wider Matrix (Guangzhou) Technology Co., Ltd. is a scientific and technological enterprise that attaches importance to R&D and user experience. We started to research and develop automated vending solutions in 2016, and achieved a leading position in the field of interactive vending machines.

With years of experience in automated retail technology, we've perfected our puzzle vending machines through rigorous testing and continuous innovation. Our commitment to quality and user experience has allowed us to expand globally, with our products now operating successfully in more than 130 countries including the United States, Canada, throughout Europe, Southeast Asia, Australia, and Israel.

We set up overseas warehouses in the United States, Canada, Britain and Israel to provide customers with consumables and accessories support. All machines support remote cloud management, which has the advantages of easy operation, convenient maintenance and high operating efficiency. After our puzzle vending machines are delivered and put into use, they can bring you considerable benefits.

Every customer's success and satisfaction are the driving force for us to pursue innovation and climb the peak forever. In the future, we will uphold the business philosophy of customer first and quality first, and constantly create more good products for the market. Join us now and start your intelligent and innovative vending machine business!

Exclusive Services

Overseas Support Service

Local transfer warehouse support, ensuring your operational stability.

Custom Design

We offer machine appearance customization, branding, and large-scale custom packaging services.

Initial Tools & Spare Parts Kit

Machine comes with complementary tools and spare parts kit, including initial consumables package for early operations.

Functional Customization & Software Optimization

Custom functionality based on client needs, including hardware and software optimization updates.

Lifetime Technical Support & Updates

We provide lifetime technical support and software update services for all customers.

Frequently Asked Questions

Why does my cotton candy machine spit sugar instead of making cotton candy?

The most common reasons are using the wrong type of sugar, improper temperature settings, or a dirty machine. Follow our troubleshooting steps above to identify and fix the specific issue with your machine.

Can I use regular sugar in my cotton candy machine?

While possible, regular granulated sugar often doesn't work well. It's better to use extra fine sugar or specialty cotton candy sugar. Some machines require sugar mixed with flossine for optimal results.How often should I clean my cotton candy machine?

For home use, clean after every session. For commercial use, clean multiple times per day depending on usage. Always follow your manufacturer's specific cleaning recommendations.What temperature should my cotton candy machine be set at?

Most machines operate best between 320-350°F (160-175°C), but check your specific model's manual for exact temperature recommendations as this can vary by manufacturer.Are Wider Matrix's commercial cotton candy machines less prone to sugar spitting issues?

Yes, Wider Matrix's commercial cotton candy vending machines are engineered with advanced temperature control and sugar feeding mechanisms that significantly reduce common issues like sugar spitting. Their automated systems maintain consistent operation for high-volume commercial use.Why does my machine work fine at first but then start spitting sugar?

This typically indicates either overheating (causing the sugar to burn rather than melt) or sugar buildup in the machine components. Try reducing continuous operation time and ensure thorough cleaning between batches.Can humidity affect my cotton candy machine's performance?

Yes, high humidity can cause sugar to clump and not melt properly. Store sugar in airtight containers and consider using a dehumidifier in humid environments.Customer Reviews

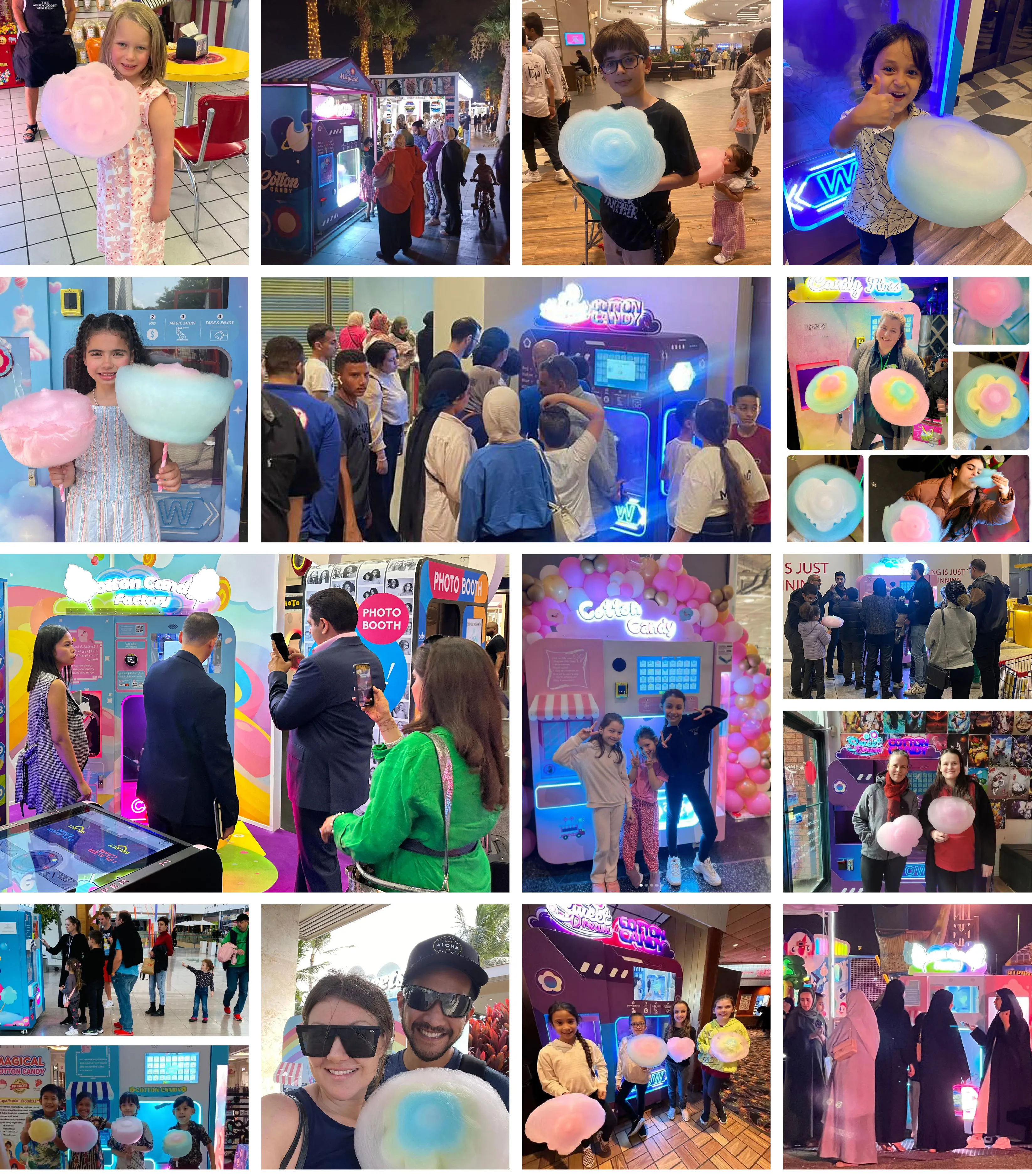

The cotton candy vending machine from Widermatrix has been an incredible addition to our theme park. Visitors are amazed by the automated process and variety of designs. The machine operates flawlessly even during peak hours, and the cloud management system makes monitoring and maintenance incredibly simple.

I installed three cotton candy machines in my shopping malls, and they've been running perfectly for over four months. The 54 different candy designs are a huge hit with customers of all ages. Sugar consumption is exactly as advertised, and the remote monitoring system allows me to check inventory levels without visiting each location.

As a first-time business owner, the cotton candy vending machine has exceeded my expectations. The colorful designs attract crowds at my family entertainment center, and children are mesmerized watching the automated process. The payment system accepts all methods as advertised, and technical support has been outstanding whenever I've had questions.

The cotton candy vending machine has revolutionized our carnival business. Setup was straightforward, and the machine began generating profits from day one. The power consumption is exactly as specified, and the machine handles high-volume periods without any issues. The variety of candy designs keeps customers coming back to try new patterns. Perfect investment for event businesses.

Our cotton candy vending machine achieved ROI within just five months! The 300kg machine is surprisingly easy to maintain despite heavy daily use. We love how the machine creates perfect cotton candy designs consistently, and our customers are always delighted by the experience. The technical team responds quickly whenever we need assistance with new features.

I operate several food courts and decided to add cotton candy machines to diversify offerings. The WM980 model has been phenomenal - customers are fascinated by the automated process and unique designs. The branding customization option allowed us to match our corporate identity perfectly. The machines have become such attractions that we've ordered five more for our newest locations.

Excellent cotton candy machine, though installation took longer than expected due to its size (132cm*195cm*67cm). Once operational, performance has been outstanding. The 54 different candy designs are a huge hit with our customers. Sugar consumption is efficient at 28-30g per candy. Technical support was very responsive when we needed help configuring the payment system.

Our university cafeteria installed this cotton candy machine six months ago, and it's been a massive success. Students are fascinated by the automated process and artistic designs. Even during rush periods, the machine handles high demand without issues. The power efficiency is impressive - only 500W on standby as advertised. The cloud management system makes inventory tracking and maintenance scheduling incredibly simple.

As the owner of a candy store chain, adding this cotton candy machine was the best decision I've made. It's become the centerpiece attraction in our flagship store. The machine creates beautiful cotton candy art that customers photograph and share on social media, bringing in new customers daily. The multiple payment options (Coin/Cash/Credit Card/NFC) accommodate all customer preferences. Worth every penny!

Our airport lounge installed the WM980 cotton candy machine eight months ago, and it's been operating flawlessly 24/7. Travelers are delighted by the unexpected treat, especially families with children during long layovers. The machine's reliability is impressive - zero downtime despite constant use. The remote monitoring system allows our staff to check sugar levels and maintenance needs without interrupting service. A perfect addition to our premium lounge experience.

rapid response

Interested in the product? Fill out the form now to get more information.