Phone Case Machine Maker: The Ultimate Guide to Manufacturing & Customization Equipment

Service Support

- ✓ Support for small batch customization

- ✓ Fast delivery worldwide

- ✓ 12-month warranty service

- ✓ Online technical support

In today’s fast-paced mobile accessory market, having the right phone case machine maker can make the difference between thriving and merely surviving.

Whether you’re a manufacturer looking to scale production or an entrepreneur exploring automated retail solutions like phone case vending machines, understanding the technology behind case production is crucial. This comprehensive guide explores all aspects of phone case manufacturing equipment, from industrial-grade machines to innovative retail solutions that are revolutionizing how consumers access customized phone protection.

Types of Phone Case Making Machines

The phone case manufacturing industry utilizes various specialized machines, each suited for different production needs and materials:

1. Injection Molding Machines

These industrial workhorses dominate mass production of plastic phone cases. They work by injecting molten material (typically TPU, polycarbonate, or ABS) into precision molds at high pressure.

- Vertical injection molders: Compact machines ideal for smaller operations

- Horizontal injection molders: High-capacity systems for large-scale production

- Multi-material machines: Can combine rigid and flexible materials in one case

2. Vacuum Forming Machines

More affordable than injection molding, these machines heat plastic sheets then form them over molds using vacuum pressure. Perfect for prototyping and small batches.

3. CNC Routers

Used for precision machining of wood, metal, or composite phone cases. Allows for intricate designs and premium finishes.

4. 3D Printers

Growing in popularity for custom and low-volume production. Modern industrial 3D printers can use materials ranging from flexible TPU to carbon fiber composites.

5. Automated Customization Systems

These innovative solutions, like those developed by Wider Matrix, allow for on-demand personalization through digital printing, laser engraving, or instant case vending.

Key Considerations When Choosing a Phone Case Machine

| Factor | Small Business | Medium Enterprise | Large Manufacturer |

|---|---|---|---|

| Production Volume | 100-500 units/day | 500-5,000 units/day | 5,000+ units/day |

| Machine Type | Desktop 3D printers, small vacuum formers | Mid-range injection molders, CNC routers | Industrial injection molding lines |

| Automation Level | Manual/semi-automatic | Semi-automatic with some automation | Fully automated production lines |

The Rise of Automated Retail Solutions

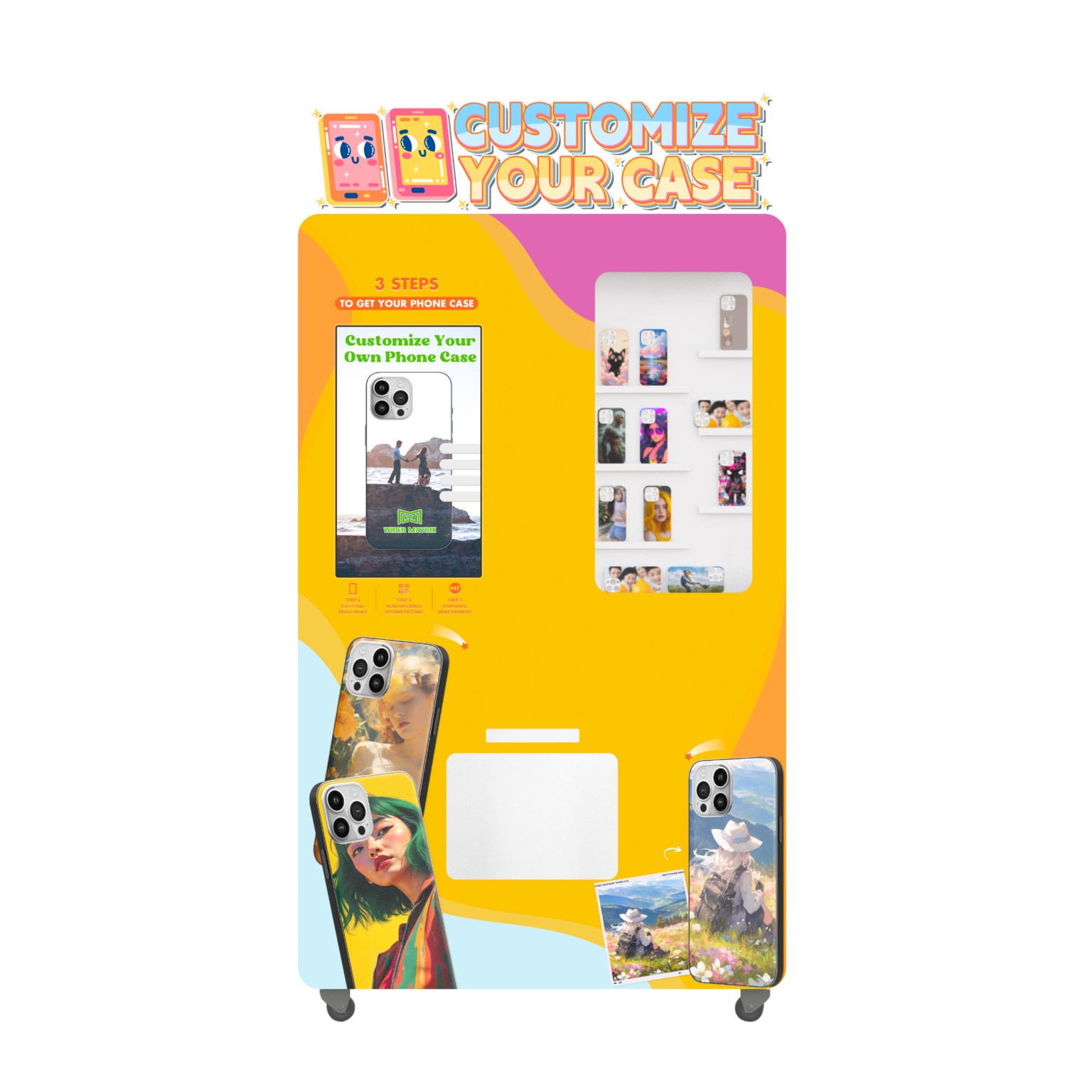

Beyond traditional manufacturing, automated retail solutions are transforming how phone cases reach consumers. Companies like Wider Matrix (gz) Technology Co., Ltd. have pioneered innovative phone case vending machines that allow customers to create fully customized cases in under a minute.

These machines combine:

- Touchscreen interfaces for design customization

- High-resolution printing technology

- Instant curing systems

- Secure payment processing

Such solutions are particularly valuable for:

- Retail stores looking to expand product offerings

- Malls and entertainment venues seeking interactive experiences

- Entrepreneurs exploring vending machine side hustles

Maintenance and Operation Best Practices

Proper maintenance ensures your phone case production equipment delivers optimal performance:

Daily Maintenance

- Clean molds and printing surfaces

- Check material levels and quality

- Verify temperature and pressure settings

Weekly Maintenance

- Lubricate moving parts

- Inspect electrical components

- Calibrate measurement systems

Quarterly Maintenance

- Replace worn components

- Update software/firmware

- Complete thorough system diagnostics

Conclusion

The phone case machine maker industry offers diverse solutions for every production need, from industrial-scale manufacturing to innovative retail automation. Whether you’re establishing a production facility or exploring automated retail opportunities with solutions like those from Wider Matrix, understanding the available technologies and their applications is key to making informed investment decisions. As consumer demand for customized, on-demand products grows, automated solutions that combine manufacturing with direct retail delivery are becoming increasingly valuable in the mobile accessories market.

Specifications

| Model | WM880 |

| Device Dimensions | 128cm*87cm*230cm |

| Device Weight | 220KG |

| Power | 220W |

| Voltage | 220V/110V (Optional) |

| Payment Methods Supported | Coin/Cash/Credit Card/NFC/WeChat/Alipay |

| Printing Technology | 6-color UV printing |

| Printing Resolution | 1440DPI |

| Printing Speed | 2-3 minutes/piece |

| Supported Phone Models | 96 mainstream models |

| Phone Case Storage Capacity | 300-500 pieces |

| Display Screen | 27-inch touch display, supports video ad rotation |

| Remote Management | Supports cloud monitoring and management |

Product Certificates

CB

CN61098

UKCA

JAT24110102514136

RoHS

JAT23122602137123

Company Introduction

Wider Matrix (Guangzhou) Technology Co., Ltd. is a scientific and technological enterprise that attaches importance to R&D and user experience, We started to research and develop vending machines in 2016, and achieved a leading position in the field of unattended vending machines.

In 2019, we manufactured the first automatic cotton candy vending machine. After testing in domestic market, refining our product for years, fixing the issues you might run into while operating, the performance of our machines are stable enough and reach the standard for export finally. Till now, our machine has been exported to more than 130 countries such as the United States,Canada,Europe, Southeast Asia, Australia and Israel.

We set up overseas warehouses in the United States, Canada, Britain and Israel to provide customers with consumables and accessories support. All machines support remote control, which has the advantages of easy operation, convenient maintenance and high operating efficiency. After our cotton candy vending machines are delivered and put into use, they can bring you considerable benefits.

Every customer's success and satisfaction are the driving force for us to pursue innovation and climb the peak forever. In the future, we will uphold the business philosophy of customer first and quality first, and constantly create more good products for the market. Join us now and start your intelligent and innovative vending machine business!

Exclusive Services

Overseas Support Service

Local transfer warehouse support, ensuring your operational stability.

Custom Design

We offer machine appearance customization, branding, and large-scale custom packaging services.

Initial Tools & Spare Parts Kit

Machine comes with complementary tools and spare parts kit, including initial consumables package for early operations.

Functional Customization & Software Optimization

Custom functionality based on client needs, including hardware and software optimization updates.

Lifetime Technical Support & Updates

We provide lifetime technical support and software update services for all customers.

Frequently Asked Questions

1. What's the difference between industrial phone case machines and vending solutions?

Industrial machines are designed for mass production in factory settings, while vending solutions like Wider Matrix's phone case vending machines are designed for retail environments, allowing consumers to create customized cases on-demand.

2. How much does a basic phone case making machine cost?

Entry-level machines start around $5,000 for small vacuum formers or 3D printers, while industrial injection molding systems can exceed $100,000. Automated retail solutions typically range from $15,000-$50,000 depending on features.3. What materials can phone case machines work with?

Most machines handle common case materials like TPU, polycarbonate, and ABS. Some advanced systems can also process wood composites, metals, or biodegradable materials.4. How long does it take to produce a phone case?

Production time varies by technology: injection molding (30-90 seconds per case), 3D printing (30-120 minutes), while vending machines can produce finished cases in under 60 seconds.5. What certifications should I look for in phone case manufacturing equipment?

Look for CE, UKCA, RoHS, and other relevant safety certifications. Wider Matrix machines meet international standards including CE, UKCA, and KC certifications.6. Can phone case machines be customized for specific designs?

Yes, most modern machines allow for design customization through interchangeable molds or digital design systems, particularly automated solutions like Wider Matrix's vending machines.7. What's the minimum space requirement for a phone case production setup?

Small machines can fit in 100 sq ft, while full production lines may require 1,000+ sq ft. Vending solutions typically need just 10-20 sq ft of floor space.8. How does Wider Matrix support customers with their phone case machines?

Wider Matrix provides comprehensive support including installation, training, maintenance, and software updates for their automated solutions, backed by their global service network across 130+ countries.User Reviews

Widermatrix has been so great to work with especially Taylor. Taylor sends pictures and testimonials and data to help the decision process. Once decided the process is smooth and Taylor sends updates with pictures and videos of YOUR phone case vending machine along the way. Once it arrived the 24 hr tech support was patient with me as we worked hard to get it all dialed in. The claims are real, this automated phone case dispenser is half paid back on my initial invest just after 2 months! Kids and adults love these protective case kiosks.

I bought two phone case vending machines, and they have been in operation for over three months and are very stable. The smartphone accessory kiosks have excellent reliability and require minimal maintenance.

This is my first time running a phone case vending machine business and it looks great. The automatic mobile accessory dispenser attracts many customers in my shopping mall location.

rapid response

Interested in the product? Fill out the form now to get more information.