Bulk Phone Case Machines: The Ultimate Guide for Large-Scale Production

Service Support

- ✓ Support for small batch customization

- ✓ Fast delivery worldwide

- ✓ 12-month warranty service

- ✓ Online technical support

In today’s fast-paced mobile accessory market, bulk phone case machines have become essential equipment for manufacturers looking to meet growing consumer demand. Whether you’re running a large-scale production facility or considering entering the phone case manufacturing business, understanding the different types of machines available and their capabilities is crucial for success. This comprehensive guide will walk you through everything you need to know about bulk phone case production equipment, from sublimation printers to automated assembly systems.

Types of Bulk Phone Case Machines

The phone case manufacturing industry utilizes various specialized machines depending on the production method and materials used. Here are the most common types:

1. Injection Molding Machines

These are the workhorses of mass phone case production, capable of creating thousands of cases per day. Injection molding machines melt plastic pellets and inject them into molds under high pressure.

2. Sublimation Printing Machines

For custom-designed cases, sublimation printers transfer full-color designs onto specially coated cases using heat and pressure. These machines are ideal for DIY phone case businesses looking to offer personalized products.

3. UV Printing Machines

UV printers directly print designs onto phone cases using ultraviolet-cured inks. They offer excellent durability and can print on various materials, including plastic, metal, and wood.

4. Laser Engraving Machines

For precision etching and cutting, laser machines provide high-quality finishes on materials like wood, leather, and acrylic cases.

5. Automated Assembly Systems

Complete production lines often include automated systems for case finishing, packaging, and quality control to maximize efficiency.

Key Considerations When Choosing Bulk Phone Case Equipment

Selecting the right machines for your production needs requires careful evaluation of several factors:

- Production Volume: Estimate your daily output requirements to determine machine capacity

- Material Compatibility: Ensure the machine works with your chosen case materials (TPU, polycarbonate, etc.)

- Automation Level: Higher automation reduces labor costs but increases initial investment

- Customization Capabilities: Consider whether you need to offer personalized designs

- Space Requirements: Industrial machines often need significant floor space

- Energy Efficiency: Look for machines with energy-saving features to reduce operating costs

Companies like Wider Matrix, with their extensive experience in automation technology, have developed specialized solutions that bridge the gap between industrial production and retail customization. Their expertise in phone case vending machines demonstrates how automation can be applied across different scales of production.

Comparing Popular Bulk Phone Case Machine Types

| Machine Type | Best For | Production Speed | Initial Cost | Customization Level |

|---|---|---|---|---|

| Injection Molding | Mass production of standard cases | Very High (1000+/hr) | $$$$ | Low |

| Sublimation Printing | Custom designed cases | Medium (100-200/hr) | $$ | High |

| UV Printing | Detailed designs on various materials | High (300-500/hr) | $$$ | High |

| Laser Engraving | Premium materials & precision work | Low (20-50/hr) | $$$ | Medium |

Maximizing Efficiency in Bulk Phone Case Production

To achieve optimal results with your bulk phone case machines, consider these professional tips:

Workflow Optimization

Design your production floor layout to minimize movement between stations. A well-planned workflow can increase output by 15-20%.

Quality Control Systems

Implement automated inspection systems to catch defects early in the process, reducing waste and returns.

Preventive Maintenance

Regular maintenance schedules keep machines running at peak efficiency and prevent costly downtime.

Material Management

Proper storage and handling of raw materials ensures consistent quality in your finished products.

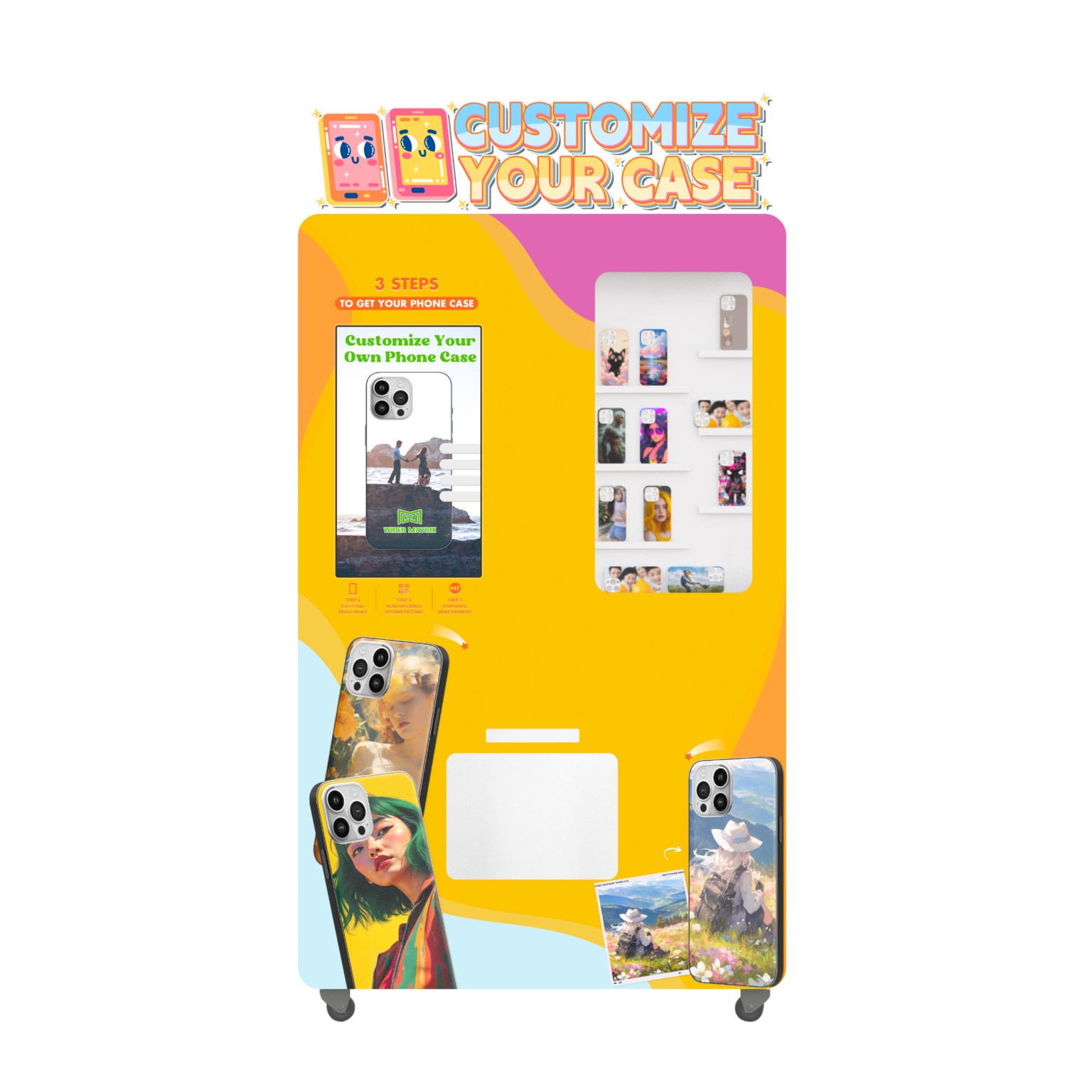

Alternative Solutions: Phone Case Vending Machines

For businesses looking to enter the phone case market without large-scale production capabilities, phone case vending machines offer an innovative solution. These automated retail solutions, like those developed by Wider Matrix, allow customers to customize and receive phone cases instantly in retail environments.

These machines combine the benefits of bulk production with the flexibility of on-demand manufacturing, making them ideal for:

- Shopping malls and retail centers

- Entertainment venues

- Transportation hubs

- College campuses

As explored in What Kind of Vending Machines Make the Most Money?, phone case vending can be a highly profitable business model with lower barriers to entry than traditional manufacturing.

Related Topics

- Can I Use My Phone to Pay at a Vending Machine?

- Mall Phone Case Vending Machines: Profit Guide 2025

- DIY Phone Case Vending: Profit Potential & Startup Guide 2025

- Custom Phone Case Vending Machine: Revolutionize Your Business with Wider Matrix

- Mobile phone case printing vending machine 2025

Conclusion

Investing in bulk phone case machines requires careful consideration of your production goals, target market, and available resources. Whether you opt for traditional manufacturing equipment or innovative solutions like Wider Matrix’s automated vending systems, the key to success lies in choosing technology that aligns with your business strategy and customer needs.

As the mobile accessory market continues to grow, companies that leverage efficient production methods while offering customization options will be best positioned to capitalize on this lucrative industry. With their global experience and certified technology, Wider Matrix represents one of many innovative approaches to meeting the world’s growing demand for phone accessories.

Specifications

| Model | WM880 |

| Device Dimensions | 128cm*87cm*230cm |

| Device Weight | 220KG |

| Power | 220W |

| Voltage | 220V/110V (Optional) |

| Payment Methods Supported | Coin/Cash/Credit Card/NFC/WeChat/Alipay |

| Printing Technology | 6-color UV printing |

| Printing Resolution | 1440DPI |

| Printing Speed | 2-3 minutes/piece |

| Supported Phone Models | 96 mainstream models |

| Phone Case Storage Capacity | 300-500 pieces |

| Display Screen | 27-inch touch display, supports video ad rotation |

| Remote Management | Supports cloud monitoring and management |

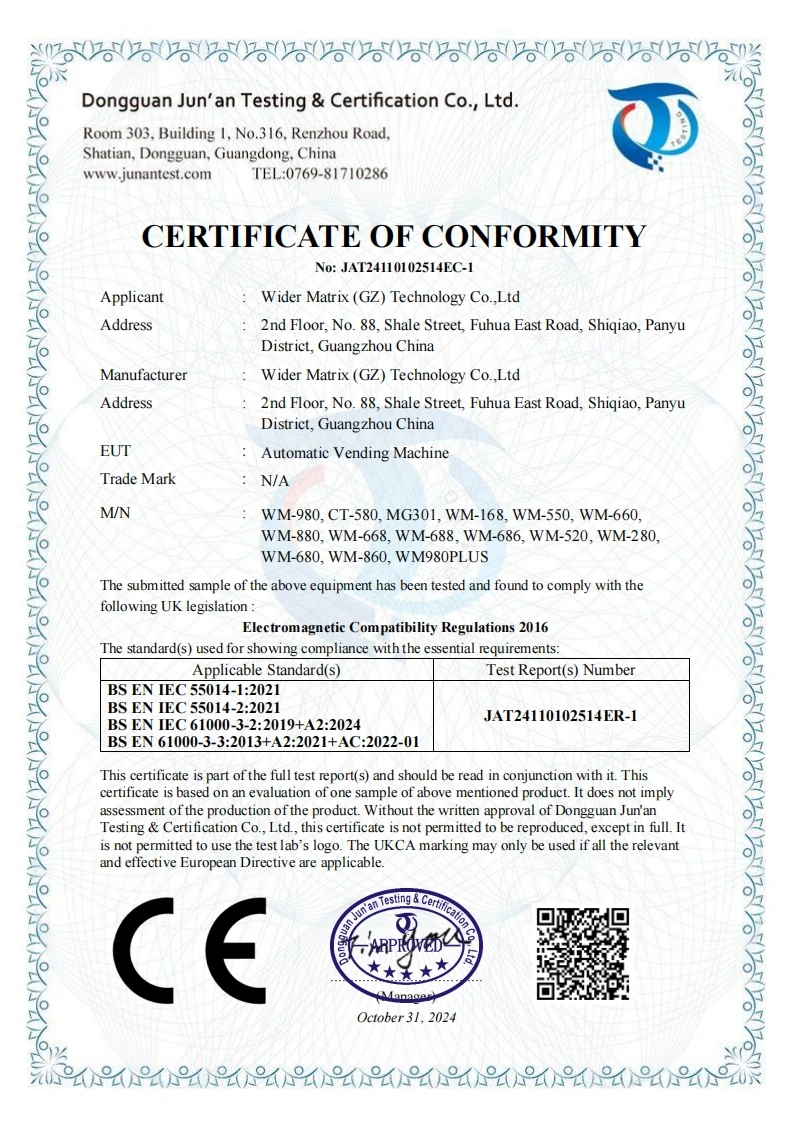

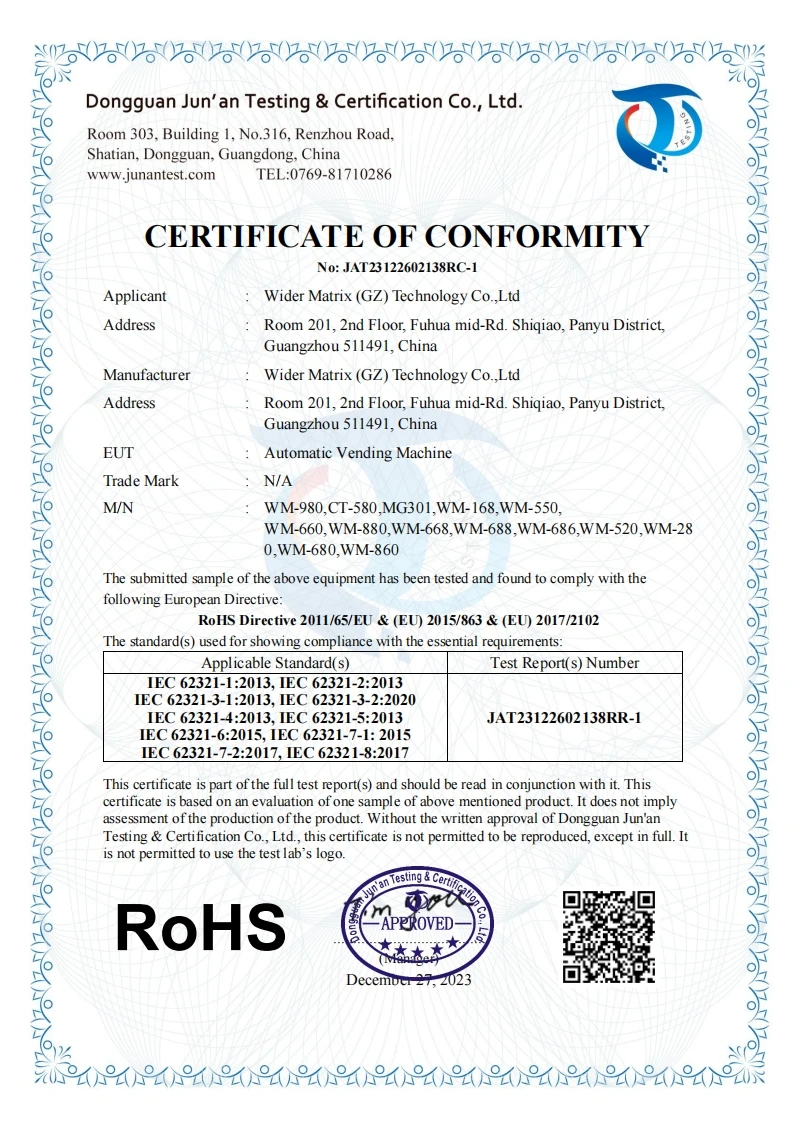

Product Certificates

CB

CN61098

UKCA

JAT24110102514136

RoHS

JAT23122602137123

Company Introduction

Wider Matrix (Guangzhou) Technology Co., Ltd. is a scientific and technological enterprise that attaches importance to R&D and user experience, We started to research and develop vending machines in 2016, and achieved a leading position in the field of unattended vending machines.

In 2019, we manufactured the first automatic cotton candy vending machine. After testing in domestic market, refining our product for years, fixing the issues you might run into while operating, the performance of our machines are stable enough and reach the standard for export finally. Till now, our machine has been exported to more than 130 countries such as the United States,Canada,Europe, Southeast Asia, Australia and Israel.

We set up overseas warehouses in the United States, Canada, Britain and Israel to provide customers with consumables and accessories support. All machines support remote control, which has the advantages of easy operation, convenient maintenance and high operating efficiency. After our cotton candy vending machines are delivered and put into use, they can bring you considerable benefits.

Every customer's success and satisfaction are the driving force for us to pursue innovation and climb the peak forever. In the future, we will uphold the business philosophy of customer first and quality first, and constantly create more good products for the market. Join us now and start your intelligent and innovative vending machine business!

Exclusive Services

Overseas Support Service

Local transfer warehouse support, ensuring your operational stability.

Custom Design

We offer machine appearance customization, branding, and large-scale custom packaging services.

Initial Tools & Spare Parts Kit

Machine comes with complementary tools and spare parts kit, including initial consumables package for early operations.

Functional Customization & Software Optimization

Custom functionality based on client needs, including hardware and software optimization updates.

Lifetime Technical Support & Updates

We provide lifetime technical support and software update services for all customers.

Frequently Asked Questions

What's the minimum space requirement for bulk phone case production equipment?

A small-scale production setup typically requires at least 500-800 square feet, while larger automated lines may need 2,000+ square feet.

How much does a complete bulk phone case production line cost?

Prices vary widely from $50,000 for basic equipment to $500,000+ for fully automated systems, depending on capacity and features.What's the production capacity of industrial phone case machines?

High-end injection molding machines can produce 1,000-2,000 cases per hour, while printing/engraving machines typically handle 100-500 units hourly.Are there eco-friendly options for phone case production?

Yes, many manufacturers now offer machines compatible with biodegradable materials like PLA and offer energy-efficient operation modes.What maintenance do bulk phone case machines require?

Regular cleaning, lubrication, and part replacement (nozzles, belts, etc.) are essential. Most manufacturers provide detailed maintenance schedules.How does Wider Matrix's approach to phone case production differ?

Wider Matrix specializes in automated retail solutions like their commercial center mobile phone case vending machine, which combines production and retail in one compact unit, eliminating the need for separate manufacturing and distribution systems.Can I start with one machine and expand later?

Many manufacturers offer modular systems that allow you to add capacity as your business grows, making it easier to scale up production gradually.8. What training is required to operate these machines?

Basic technical skills are needed, but most suppliers provide comprehensive training. Some advanced systems require specialized operators.User Reviews

Widermatrix has been so great to work with especially Taylor. Taylor sends pictures and testimonials and data to help the decision process. Once decided the process is smooth and Taylor sends updates with pictures and videos of YOUR phone case vending machine along the way. Once it arrived the 24 hr tech support was patient with me as we worked hard to get it all dialed in. The claims are real, this automated phone case dispenser is half paid back on my initial invest just after 2 months! Kids and adults love these protective case kiosks.

I bought two phone case vending machines, and they have been in operation for over three months and are very stable. The smartphone accessory kiosks have excellent reliability and require minimal maintenance.

This is my first time running a phone case vending machine business and it looks great. The automatic mobile accessory dispenser attracts many customers in my shopping mall location.

rapid response

Interested in the product? Fill out the form now to get more information.