In today’s personalized world, custom phone cases are more than just protective gear – they’re fashion statements and business opportunities. Whether you’re an entrepreneur looking to start a phone case business or a hobbyist wanting to create unique designs, choosing the right printing machine is crucial. This comprehensive guide explores all available options, from industrial UV printers to DIY-friendly 3D printers, helping you make an informed decision based on your needs and budget.

Types of Machines for Printing Phone Cases

1. UV Flatbed Printers (Best for Professional Quality)

UV printers are the industry standard for professional phone case printing. These machines use ultraviolet light to cure special inks instantly, creating durable, high-resolution prints directly on phone cases. Popular models include:

- Mimaki UJF-6042 MkII

- Roland DG VersaUV LEF-300

- PRISMA UV flatbed printers

Companies like Wider Matrix (GZ) Technology Co., Ltd often integrate these printers into their automated solutions, combining printing technology with vending capabilities for innovative retail applications.

2. Sublimation Printers (Best for Full-Color Designs)

Sublimation printing is perfect for vibrant, full-color designs on specially coated phone cases. This method requires:

- Sublimation printer (like Sawgrass Virtuoso SG500)

- Heat press machine

- Sublimation ink and transfer paper

3. 3D Printers (Best for Custom Shapes & Prototypes)

For those interested in creating completely unique case shapes, 3D printers offer unlimited possibilities. Learn more about using 3D printers for DIY phone cases in our detailed guide.

Key Features to Consider When Choosing a Machine

| Feature | UV Printer | Sublimation | 3D Printer |

|---|---|---|---|

| Print Quality | Excellent | Very Good | Good (depends on model) |

| Durability | 5+ years | 3-5 years | Varies by material |

| Startup Cost | $10,000+ | $1,000-$3,000 | $300-$3,000 |

| Best For | Professional businesses | Small businesses | Hobbyists & prototypes |

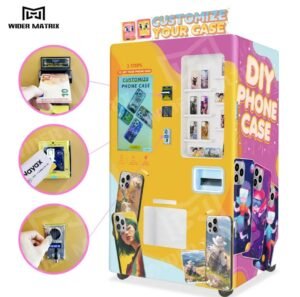

Alternative Solutions: Phone Case Vending Machines

For entrepreneurs looking for turnkey solutions, phone case vending machines offer an innovative way to sell custom cases. Companies like Wider Matrix specialize in automated vending solutions that can print and dispense personalized phone cases on demand, combining printing technology with retail automation.

Discover how to start a DIY phone case business in 2025 with our comprehensive guide covering all aspects from equipment selection to marketing strategies.

Frequently Asked Questions

1. What is the best machine for printing phone cases?

For professional results, UV flatbed printers are best. For small businesses, sublimation setups offer good quality at lower cost. 3D printers are ideal for unique case shapes.

2. Can I use a regular inkjet printer for phone cases?

No, regular inkjet printers aren’t suitable. You need specialized printers (UV, sublimation) or proper coatings for the ink to adhere and last.

3. How much does a phone case printing machine cost?

Prices range from $300 for basic 3D printers to $50,000+ for industrial UV printers. Most small businesses invest $1,000-$10,000 in equipment.

4. What materials can I print phone cases on?

Common materials include polycarbonate, TPU (for 3D printing), and specially coated cases for sublimation.

5. How long do printed phone cases last?

UV-printed cases last 5+ years, sublimation 3-5 years, and 3D-printed cases vary by material quality.

6. Can I print phone cases at home?

Yes, with smaller sublimation or 3D printing setups. Industrial UV printers typically require commercial spaces.

7. What file formats do I need for phone case printing?

Vector files (AI, EPS) are best, but high-res PNG/JPG (300dpi+) also work for most printing methods.

8. How many cases can I print per hour?

UV printers: 20-100/hour. Sublimation: 10-30/hour. 3D printing: 1-5/hour depending on complexity.

9. Do I need special software for phone case printing?

Basic design software (Photoshop, Illustrator) works for graphics. 3D printing requires modeling software like Fusion 360.

10. Where can I buy a phone case printing machine?

Specialized manufacturers, industrial equipment suppliers, or companies like Wider Matrix that offer complete solutions including custom phone case vending machines.

Related Topics

Conclusion

Choosing the right machine for printing phone cases depends on your budget, quality requirements, and business scale. While UV printers offer the highest quality for professional operations, sublimation provides an affordable entry point, and 3D printing enables unique designs. For entrepreneurs looking beyond traditional printing methods, innovative solutions like phone case vending machines from companies like Wider Matrix present exciting opportunities in the growing personalized accessories market.

Comments

No comments yet. Be the first to comment!